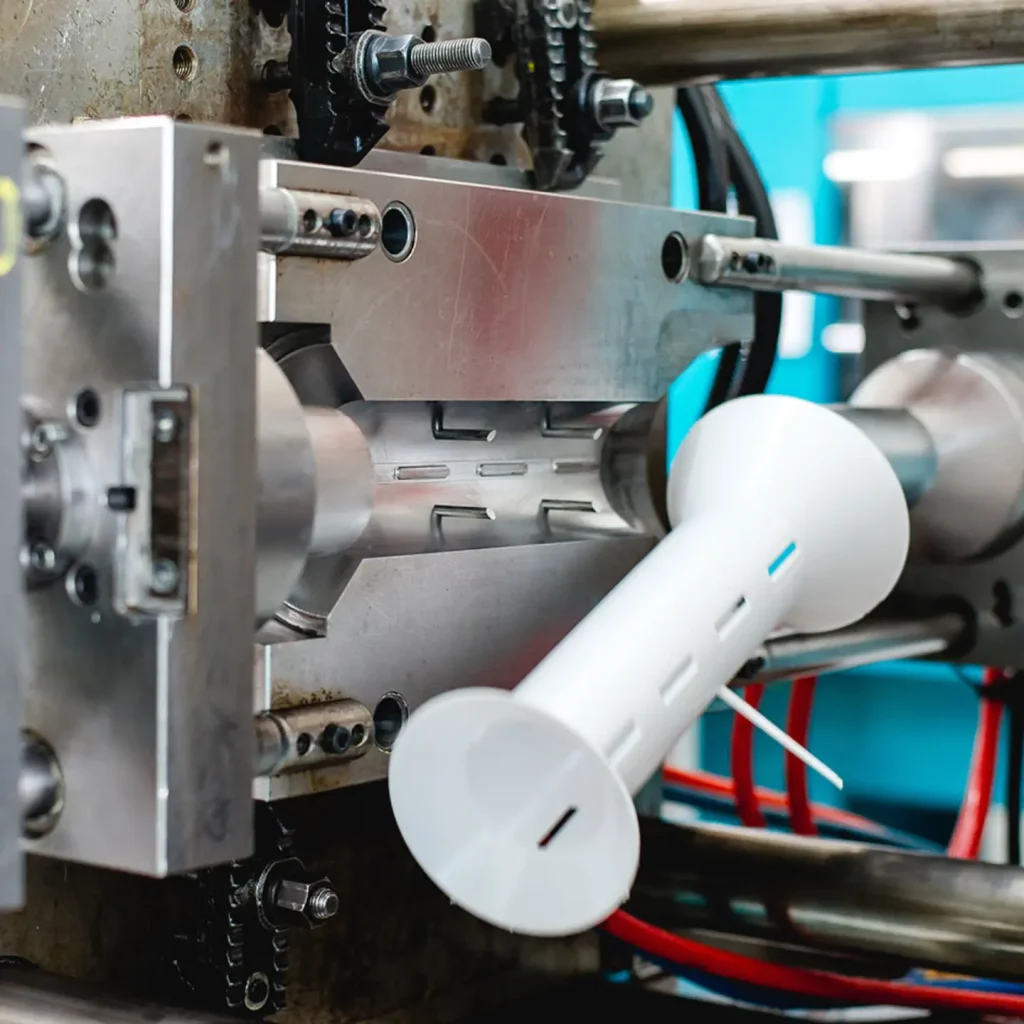

blow molded parts

- First parts available from 14 days

- own

- offer in a few hours

- manufacturing in Germany

- With every project we support the reconstruction of coral reefs

- First parts available from 14 days

- own

- offer in a few hours

- manufacturing in Germany

- With every project we support the reconstruction of coral reefs

Over 200+ companies

trust maxnext

Simply order blow molded parts online!

Blow-moulded plastic parts directly from the manufacturer.

Fast, personal communication and best price directly in the first offer.

small and large series

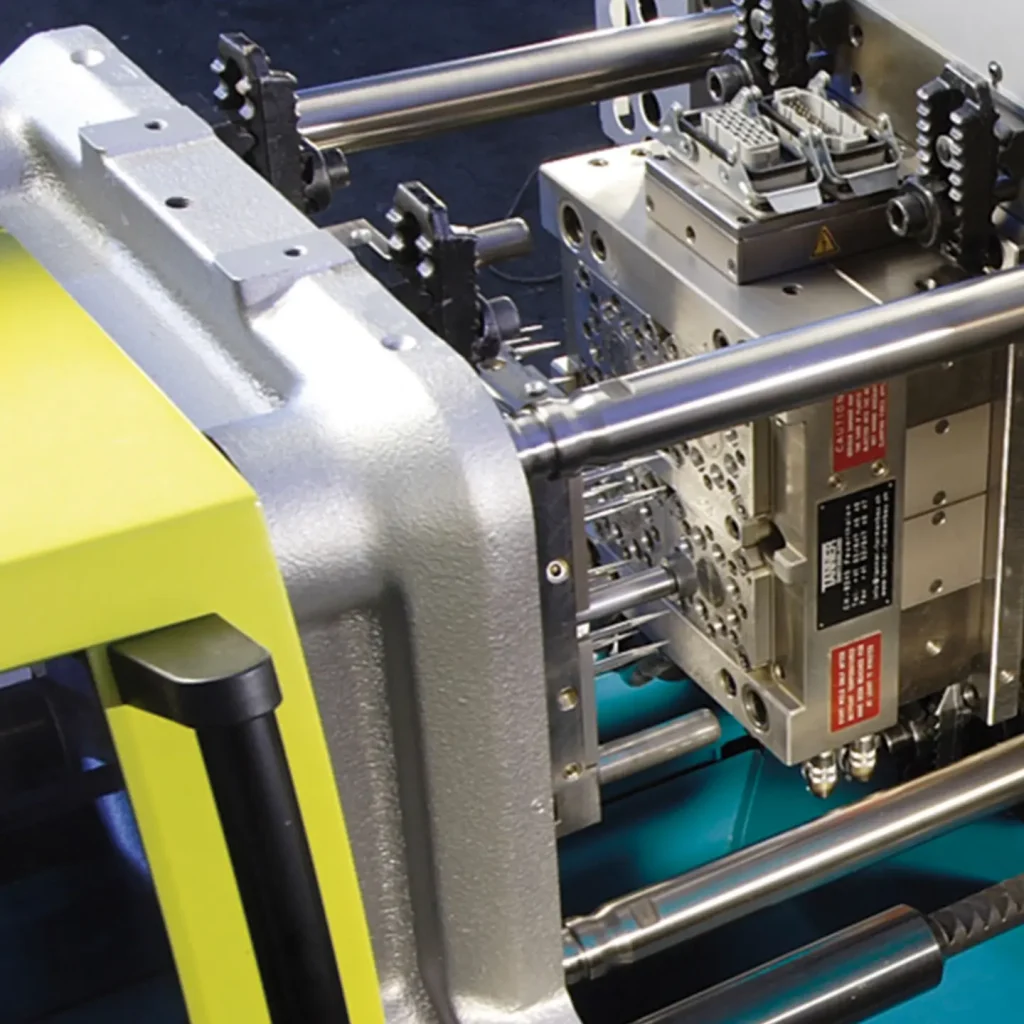

Blow moulded parts directly from the manufacturer

hollow body production from plastics

maxnext is part of the company KSE Kunststoff. The result is blow-moulded parts of unrivalled quality & in record time.

We will find the most economical solution for your project. From development to series production. From simple components to complex assemblies.

Let’s get it started!

‘Our aim was to optimise the existing plastic housings of our access points. The result: we are now independent & the purchase has become more economical.’

Winfried Zangerle

CEO @ germanhotspot.de

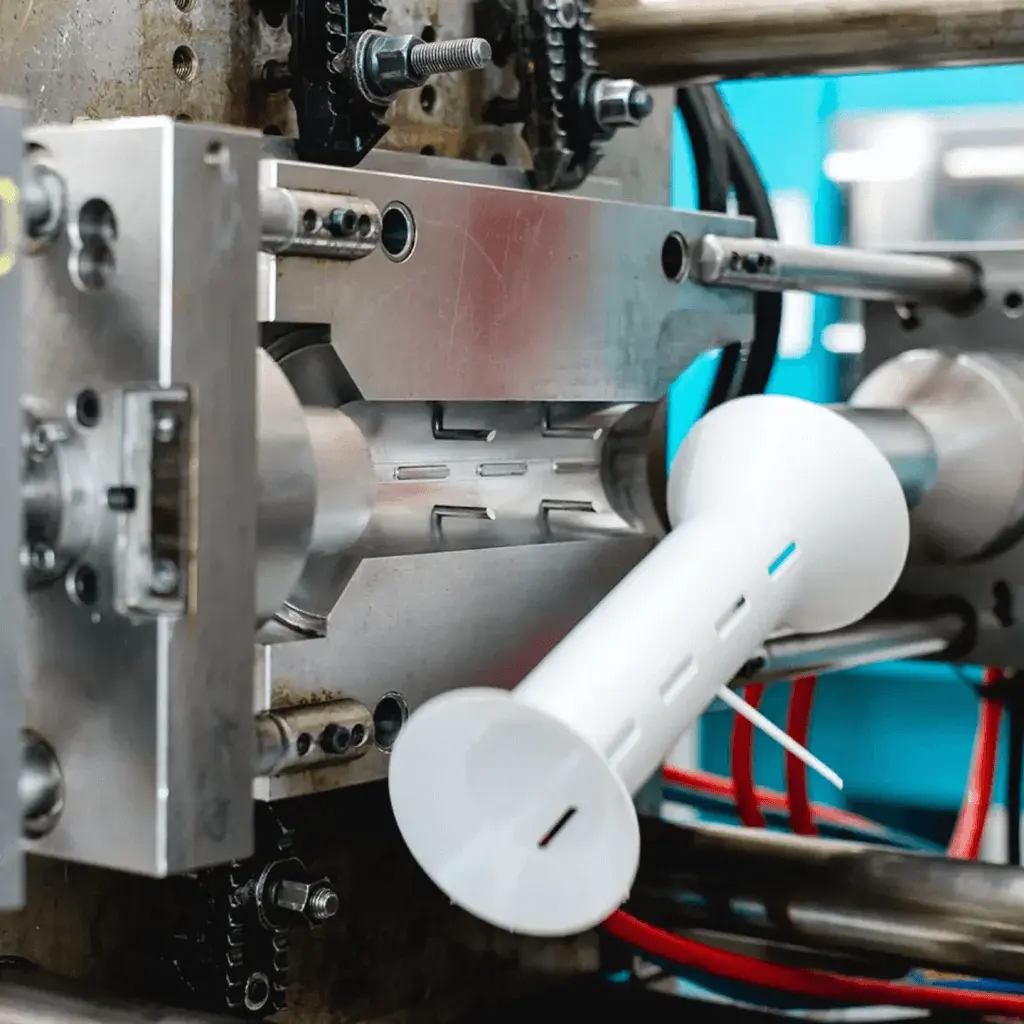

‘Fast realisation of our product design. We didn’t think this would make such an extreme difference to our sales. Thank you!’

André Becker

CEO @ expertenloft

Your manufacturer for blow molded parts

Over 25 years of experience

Simple & complex plastic hollow bodies

Personal contact person

The partner for strong brands

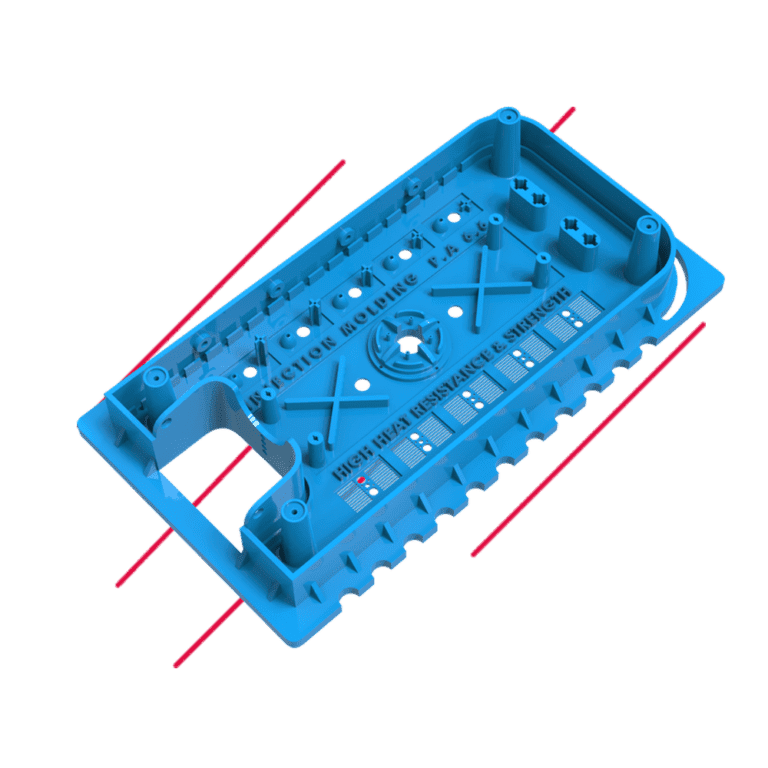

We manufacture plastic parts according to your requirements from a wide range of thermoplastics, such as ABS, PET, POM, PC, PA, PP, PS, PEEK and other technical plastics. As one of the few plastic injection molding plants, we ourselves produce larger assemblies that are assembled from individual parts.

Ideal for use with electricity.

Perfect insulating properties & fire protection thanks to fibre reinforcement. More about flame retardants in plastics.

Welding plastic parts

We offer the optimum welding process for all common plastics with our DVS 2281-trained plastic welders.

Hot gas welding,

heating element butt welding and

ultrasonic welding

cover all possible requirements in our plastics sector. In contrast to alternative methods such as riveting or screwing, welded composites ensure liquid- or gas-tight seams with a mostly smooth, trouble-free surface without notch effects. Depending on the process, this result can be maximised. Some composites of individual components require a particularly even distribution of stress, which leads to highly resilient results with the appropriate plastic welding method.

We can even produce larger assemblies without any problems.

Component assembly & device construction

We manufacture functional and mechanical assemblies in the field of device construction. We complete the plastic items produced for you with additional components such as circuit boards, switches, motors and cables, which we are happy to purchase and organise for you. Final inspections, functional tests and serial number management are of course documented in a traceable manner.

Special requests and customised designs are possible at any time!

Certifications

Request a quick quote!

All uploads are confidential & encrypted. Privacy policy

Frequently Asked Questions

Sure! Write us an e-mail with your idea and we will design / construct your product.

It's simple: send us your 3D data and we will create a suitable best price offer for you in a short time.

We send the injection moulded parts with a tracking ID. This means you always know where your plastic components are at any given time.

In a nutshell:

Product development, mould making & production under one roof. This guarantees short distances. You not only save money, but are also independent of long and fragile supply chains.

Right across the board: from A for automotive to Z for pet supplies. Whether simple components or complex technical assemblies made from high-performance plastics.

Experience from over 25 years of injection moulding guarantees the best results for your project. Request a quote now!

The following factors are important:

Plastic used

Weight of the component

Complexity of the injection moulded part

Purchase quantity

The biggest factor is the production of the injection mould. However, once this has been built, the subsequent investment is low. The more components are ordered, the cheaper they can be manufactured in a series.

Example calculation:

Yes, that's important to us! You will have a personal contact for the production of your injection moulded parts.

We support you in our state-of-the-art injection moulding plant from development to series production.