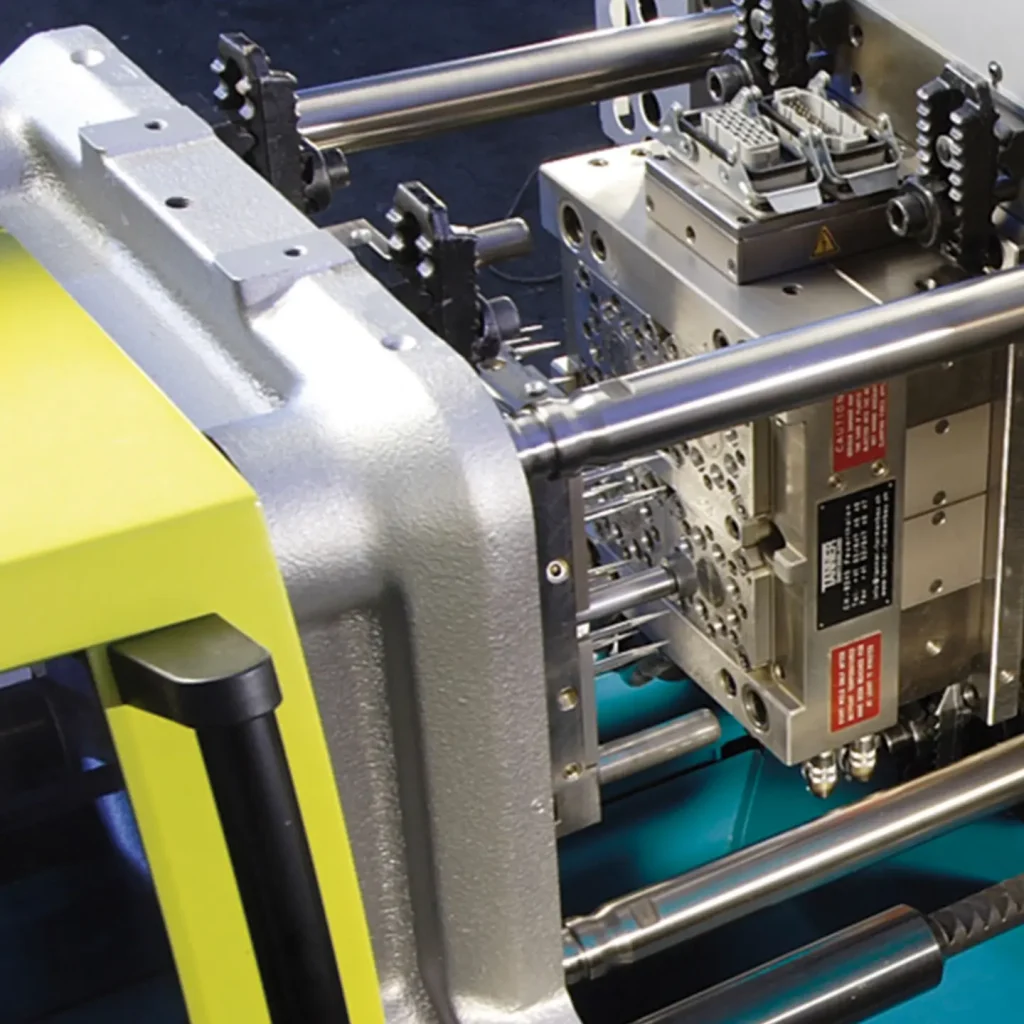

tool design for injection molding

- injection molding-compatible construction

- Mouldflow Analyse & Stückliste

- All data for CNC production

- offer in a few hours

- Toolmaking possible at the best price

- prototypes and series production

- injection molding-compatible construction

- Mouldflow Analysis & Parts List

- All data for CNC production

- offer in a few hours

Over 200+ companies

trust maxnext

Tool design: what is important?

design of tools

Fast & easy!

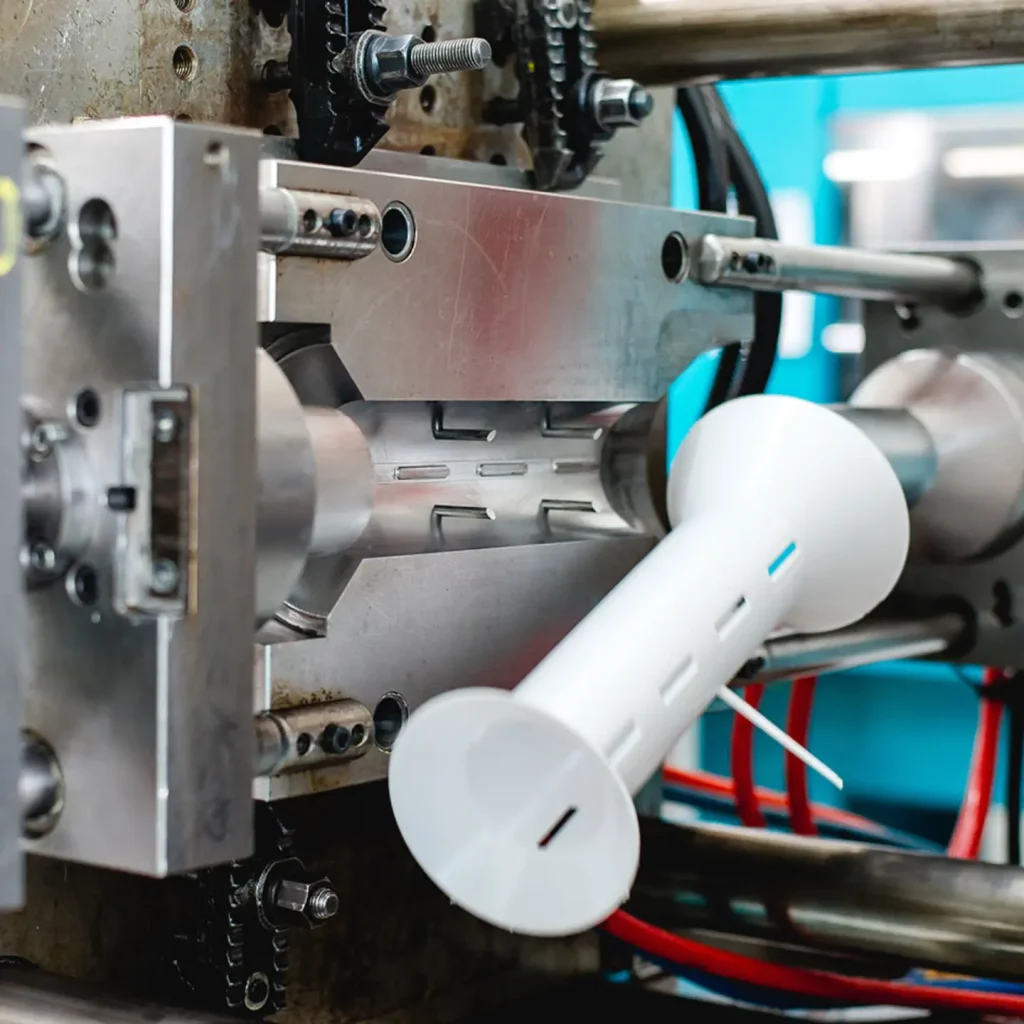

Finished data set in a few working days. For your own use or simply order tools directly from us. We produce quickly and accurately in-house Mold making.

We find the most economical solution to bring it to market. From the development, the Industrial design through to series production. From simple components to complex assemblies.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex injection-molded parts

- The partner for strong brands

- offer in a few hours

Frequently Asked Questions

Sure! Send us an email with your idea and we will design/construct your product.

In short:

Product development, mold making & manufacturing under one roof. This guarantees short routes. Not only does this save you money, but you are also independent of long and fragile supply chains.

- plastic used

- weight of the component

- complexity of the injection-molded part

- purchase quantity