mold making for injection molding tools

- tool design FREE

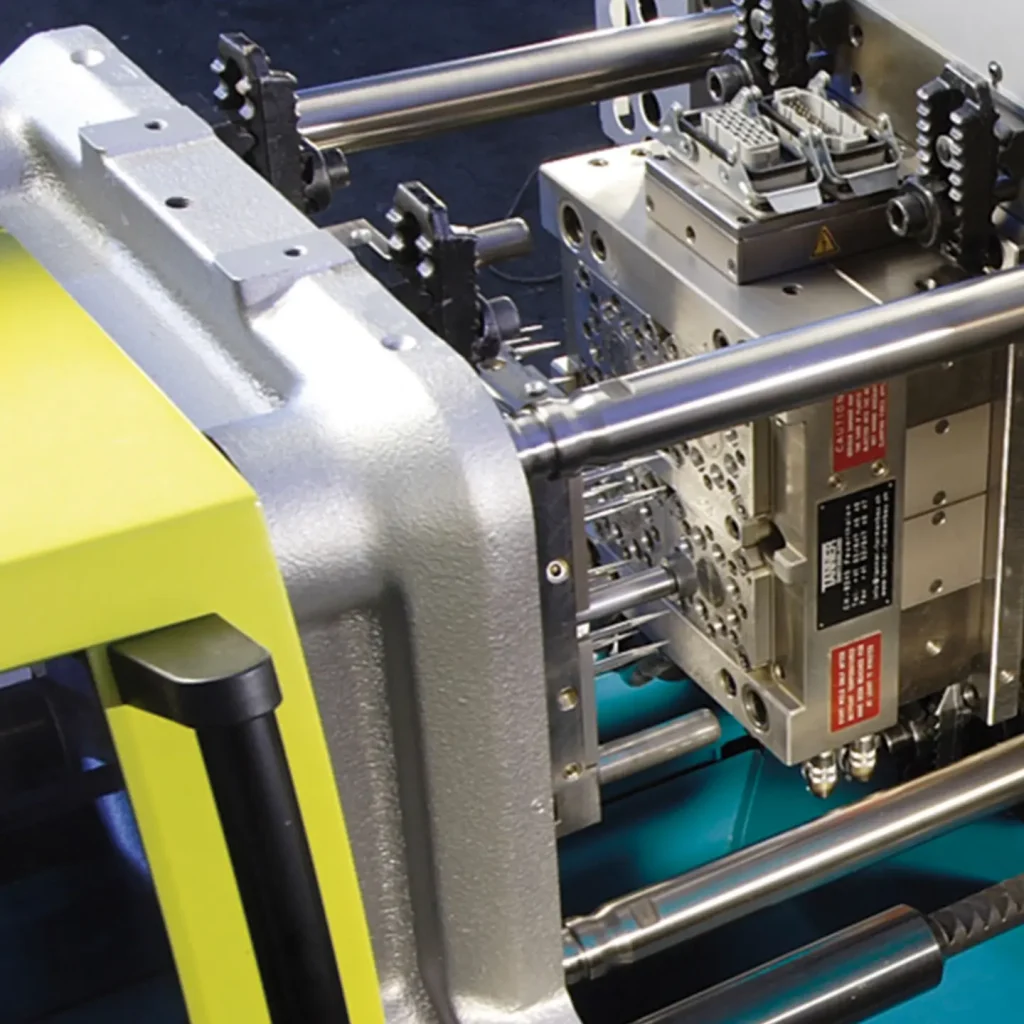

- Fully automated mold making

- offer in a few hours

- With every project we support the reconstruction of coral reefs

- Free tool design

- Fully automated mold making

- offer in a few hours

- With every project we support the reconstruction of coral reefs

Over 200+ companies

trust maxnext

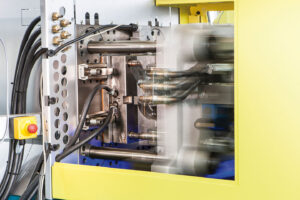

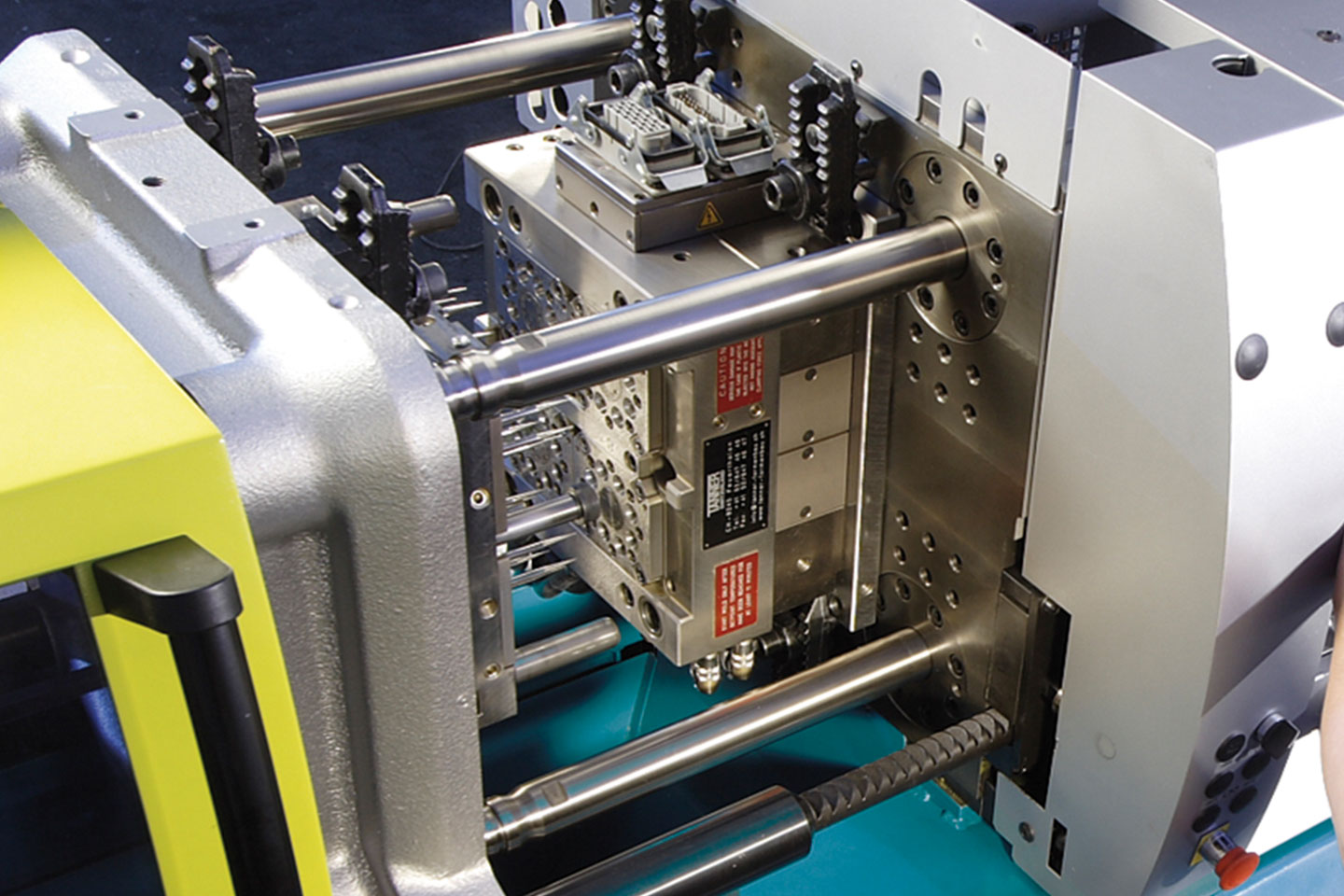

Simply order injection molding tools online!

Mold making for injection molding tools quickly and independently of long supply chains.

Fast, personal communication and best price directly in the first offer.

That fits!

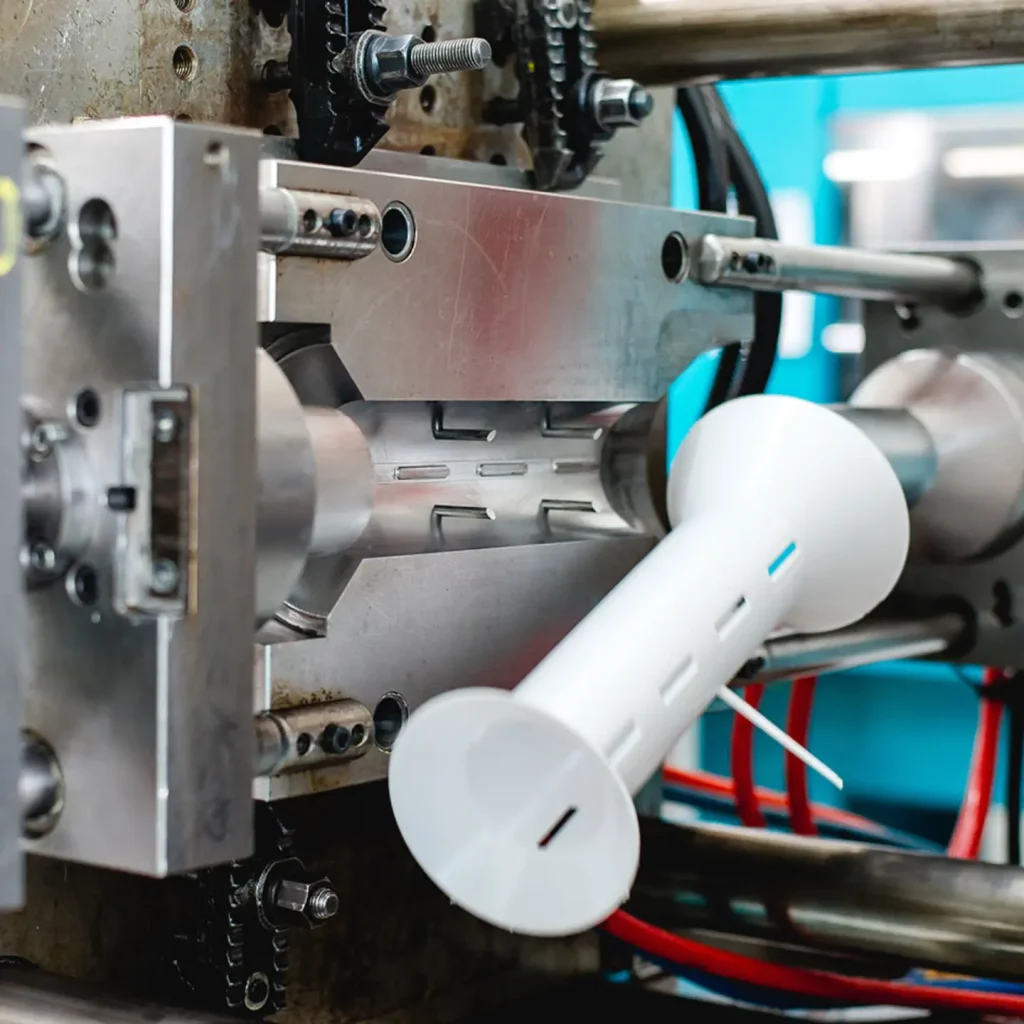

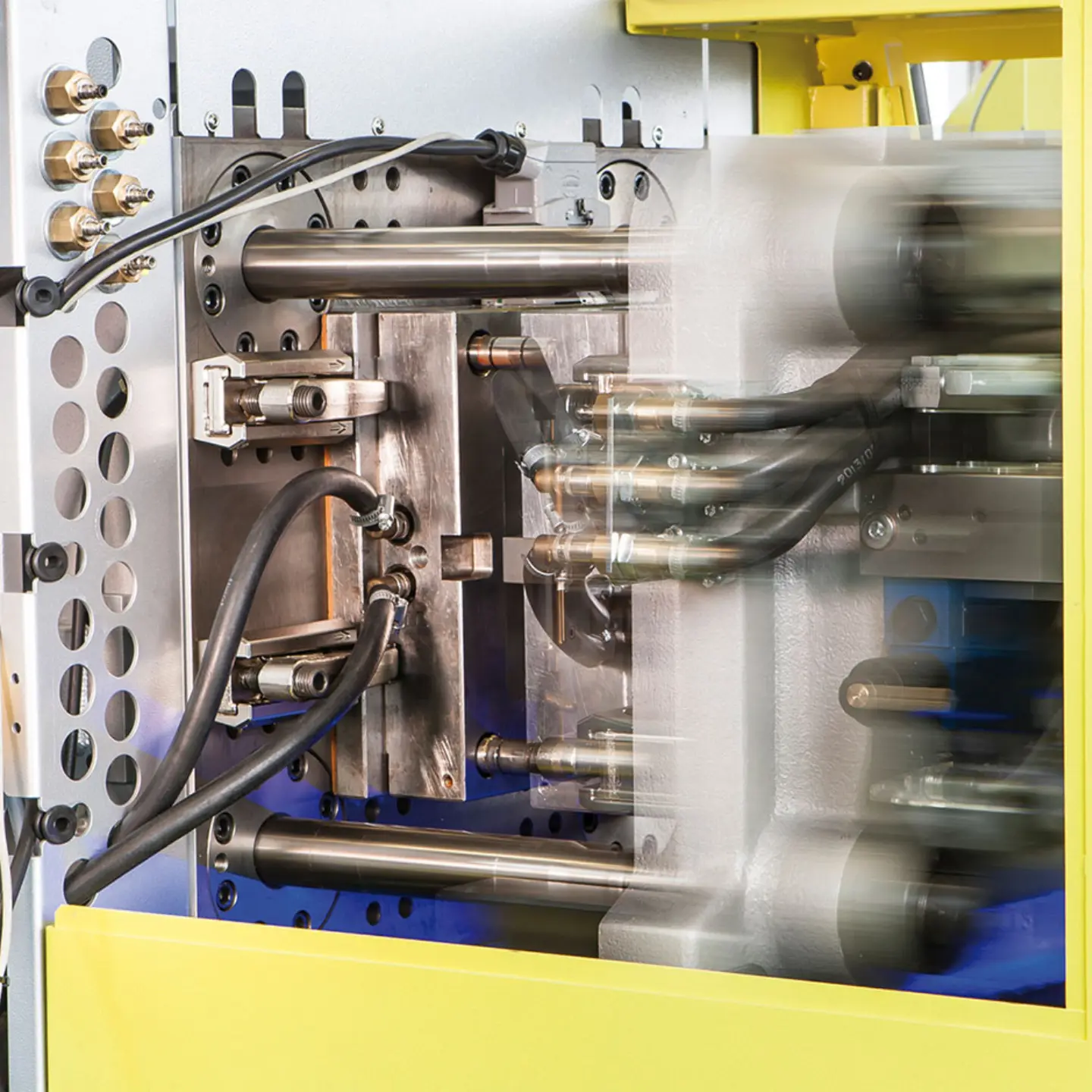

Injection molding and blow molding tools for prototypes and series production. We are the fully automated mold maker for successful projects.

Send 3D data now & receive a quote including FREE feasibility analysis.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

Mold making at the best price!

- Over 25 years of experience

- Certified

- Personal contact

- The partner for strong brands

hot runner tools

When using a hot runner system, the sprue system is always thermally separated from the rest of the mold and heated separately.

We offer hot runner tools with fast production at the best price.

Request a quote now

prototype tools

injection molds from the 3D printer

certifications

….. we have that too. In our factory near Augsburg we work according to DIN ISO without being certified. That saves money.

Our injection moulding plant near Nuremberg is certified to DIN ISO 9001 & 14001: ideal for anyone who values this.

Frequently Asked Questions

Sure! Write us an email with your idea and we will design / construct your product.

In short:

Product development, mold making and production under one roof. This guarantees short distances. Not only does this save you money, but you are also independent of long and fragile supply chains.Yes, a lot has changed. In the past, injection molds were generally made of aluminum.

The reason for this was that aluminum was particularly easy to machine. However, modern CNC milling machines can also do this with steel. Since the price difference between steel and aluminum is not decisive, but steel is significantly more durable, steel tools are increasingly being used today.

Another advantage of injection molds made of steel is that they can produce significantly higher quantities before they reach their production limit.

In summary, it can be said that today the production of steel tools is significantly more economical and sustainable than the production of aluminum tools, as the price difference hardly plays a role anymore. However, there are areas of application where an aluminum tool can make sense.

We at maxnext will be happy to advise you on choosing the right material for mold making.

Several factors are crucial for the cost of an injection molding tool. For example:

Does the component have undercuts?

Threads?

Wall thicknesses?

Cavities?

Is a hot runner tool required?

Threads?

Wall thicknesses?

Cavities?

Is a hot runner tool required?

Yes, that is important to us! You will get a personal contact for the production of your injection molded parts.

We accompany you in our state-of-the-art injection molding plant from development to series production.