We show how 3D printing improves tool production for injection molding. 3D printing has become very important in recent years. It is changing how we do manufacturing.

3D printing enables companies to improve their production processes. They save money and time. We would like you to find out more about this technology.

Important findings

- 3D printing optimizes tool production for injection moulding processes.

- The technology reduces costs and saves time.

- Freedom of design is a key feature of 3D-printed molds.

- The use of 3D printing enables innovative production solutions.

- Sustainability is promoted through the use of environmentally friendly materials.

Introduction to 3D printing technologies

3D printing is a new way of making complex things. It uses different techniques that are selected according to requirements. Materials are applied layer by layer to form the desired object.

Fused deposition modeling (FDM) and stereolithography (SLA) are two of the best-known methods. They are used in many areas.

What is 3D printing?

3D printing converts digital models into real objects. It saves material and reduces waste. This makes production faster and more flexible.

History of 3D printing

The history of 3D printing began in the 1980s. Back then, the aim was to make prototypes quickly. Since then, the technology has developed considerably.

The first machines produced simple molds. Today, there are complex systems for industry. Companies use 3D printing to develop new products and reduce costs.

Advantages of 3D-printed molds

Additive manufacturing offers many advantages for mold production. Companies that value cost efficiency and flexibility benefit in particular. The technology is revolutionizing the manufacturing process and opening up new possibilities in product development.

Cost efficiency and time savings

3D-printed molds reduce material waste and thus lower costs. Manufacturing times are often reduced from weeks to hours or days. The digital process enables quick adjustments to the design.

This flexibility allows companies to react quickly to changes in the market. The advantages are particularly great for prototypes and small series. More information can be found here.

Design freedom and flexibility

3D printing enables complex geometries that would otherwise be difficult to implement. This promotes innovative solutions and shortens the development cycle. Companies bring their products to market faster and more efficiently.

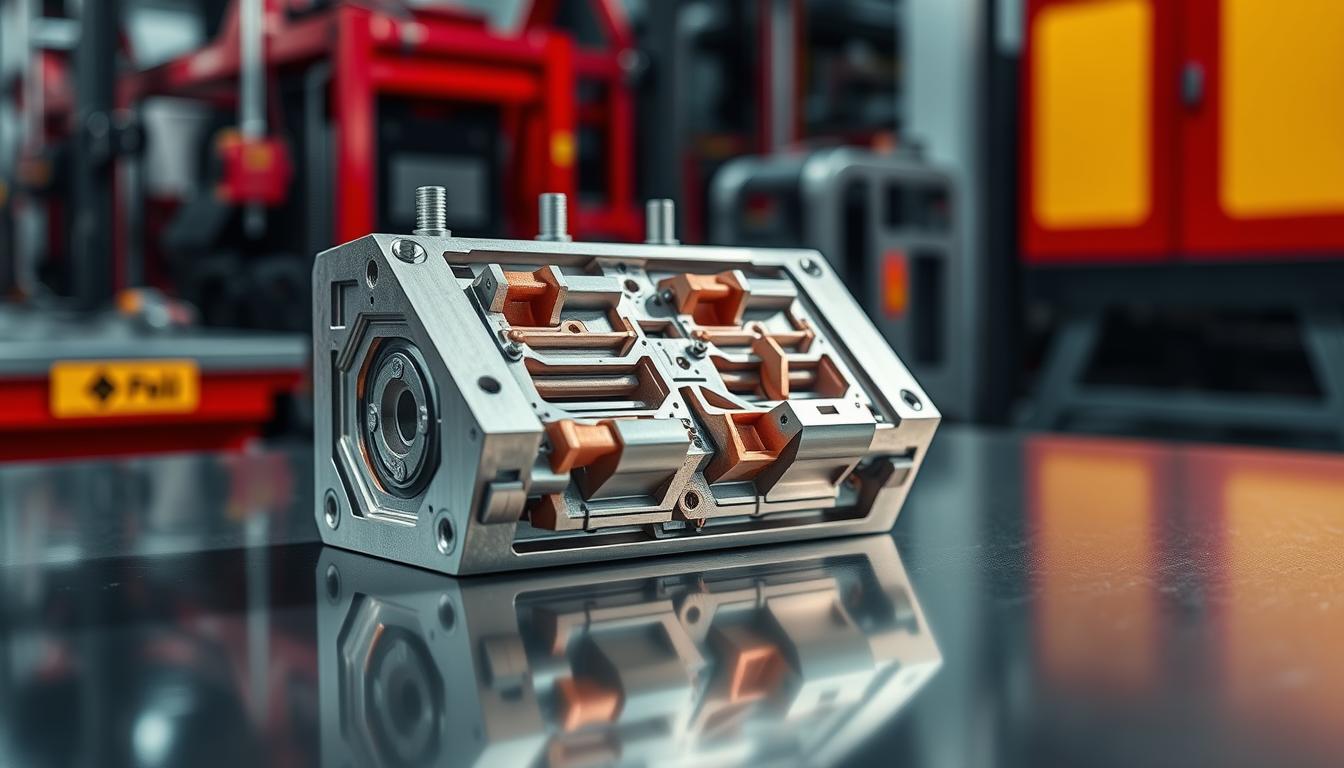

The ability to test different designs without high additional costs increases their chances of success. A picture of the advantages is shown in the following figure:

Tool production with 3D-printed molds

The use of 3D-printed materials in tool manufacturing is changing the industry. First, an accurate 3D model is created. This model is very important and is used for mold production. The choice of 3D printing process influences how good the parts will be.

Overview of the process

The process of producing 3D-printed molds involves several steps:

- Creation of the digital 3D model.

- Selection of the appropriate 3D printing process.

- Carrying out the printing process with special 3D-printed materials.

- Post-processing to ensure quality.

An automated process makes the process more efficient and shortens the time. It is important to find out about best practices in tool manufacturing.

Materials for mold production

The choice of material is decisive for the quality and durability of the products. The most common materials are

- Thermoplastics

- Improved composite materials

- Metal powder for special applications

Each material has its strengths and is better suited to certain requirements. The right choice is important for the success of the products.

Use in the injection molding industry

The injection molding industry has gained a lot from 3D-printed moulds. This technology makes production more efficient and cheaper. It is used in many industries where it works well.

Industry applications

3D-printed molds are versatile. They are used in areas such as:

- Automotive industry – for prototypes and spare parts.

- Electronics – for precise housings and components.

- Consumer goods – for unique designs and fast market launches.

This technology is quickly adaptable and saves time.

Integration into existing production lines

Introducing 3D-printed molds into existing production lines is easy. Companies can:

- Save time and work more efficiently.

- Make tool changes more expensive.

- React more quickly to market changes.

3D printing technologies are improving production processes in the injection molding industry.

Technological developments in 3D printing

The world of 3D printing is developing rapidly. New technologies not only increase efficiency. They also enable the production of more complex designs. We take a look at the latest developments and material research that will influence the future.

Latest innovations

New printing technologies and better machines lead to faster production times. The quality of surfaces is also improving. Advances in metal and ceramic printers are particularly noteworthy. These make it possible to produce high-quality parts faster and open up new industrial applications.

Materials research and development

Research is improving existing materials and developing new ones. These new materials meet specific requirements such as higher temperature resistance. The further development of materials is crucial in order to meet increasing requirements.

| Innovations | Advantages |

|---|---|

| Metal and ceramic printers | Increased precision, improved surface quality |

| New printing technologies | Faster production times |

| Improved existing materials | Higher durability and adaptability |

Customization of the 3D-printed shapes

The customization of 3D printed molds is very important. It helps to fulfill specific projects. Modern technologies make it possible to change designs quickly and easily.

This flexibility is crucial for customized solutions.

Design customizations for specific projects

One important point is the customization of designs. Companies can react quickly to changes with 3D printing. This results in products that precisely match customer requirements.

Some advantages of customizable designs are:

- Optimum functionality for individual applications

- Increased efficiency through specific adaptations

- Leaner processes through rapid iteration and prototyping

Individual design adaptations not only improve functionality. They also rationalize production. This leads to greater customer satisfaction, as products are manufactured exactly according to customer requirements.

Learn more about our 3D printing services. Discover how we can help you find the perfect customizations for your projects.

Sustainability through 3D printing

Sustainability is becoming increasingly important in manufacturing. 3D printing has many advantages, especially when it comes to environmentally friendly materials and less waste. Companies can thus reduce their ecological footprint.

Environmentally friendly materials

The focus is on recyclable materials and bio-based plastics. Companies are looking for fully degradable materials. These protect the environment and are suitable for modern production facilities.

These environmentally friendly options could revolutionize manufacturing. They could greatly reduce the use of non-sustainable raw materials. For more information on eco-friendly 3D printing, visit this link.

Reduction of waste

A major advantage of 3D printing is the efficient use of materials. Only the necessary material is used, which greatly reduces waste. This method saves resources and reduces excess material.

Companies achieve their environmental goals through such practices. They also save costs in the process.

Challenges and solutions

Companies face many challenges in the field of 3D printing. These affect quality and efficiency. Technical problems are often decisive for the success of 3D-printed molds.

Technical hurdles in 3D printing

There are many technical challenges when introducing 3D printing technologies. These include precision and post-processing. It is important to find innovative solutions to solve these problems.

Long-term stability of the molds

The stability of 3D-printed molds is very important. The service life can be increased through material research and optimization of the printing parameters. A focus on stability ensures product quality and strengthens customer confidence.

Future outlook for 3D printed molds

The market for 3D-printed molds is developing positively. Demand is increasing, particularly in the automotive and consumer goods industries. It is expected that 3D printing will become a key technology in manufacturing.

Companies are recognizing the advantages of these innovative methods. They bring new possibilities for production.

The future looks promising. New materials promise shorter production times and lower costs. Research in materials science and printing technologies is creating innovative applications.

This progress will revolutionize the industry. It opens up new possibilities for customized solutions.

We are at the beginning of a new era. The further development of these technologies will make production more efficient. It will change the way products are manufactured.

The future of 3D printing is promising. It will play an important role in next-generation manufacturing.

FAQ

What are the advantages of using 3D printed molds for injection mold production?

3D-printed molds have many advantages. They are cost-effective and save time. They also allow more freedom of design.

This enables companies to reduce their costs. They can react faster and produce complex shapes that would otherwise not be possible.

How exactly does the process of tool production with 3D printing work?

The process begins with a digital 3D model. The appropriate 3D printing process is then selected. Finally, the mold is printed.

The entire process is automated. This increases efficiency and precision.

What materials are used for the production of 3D printed molds?Welche Materialien werden für die Herstellung von 3D-gedruckten Formen verwendet?

Various materials are used for production. These include thermoplastics and special composite materials. The choice depends on the project requirements.

In which industries are 3D printed molds mainly used?

3D-printed molds are used in many industries. These include the automotive, electronics and consumer goods industries. They enable fast and cost-efficient production.

How can 3D printing be integrated into existing production lines?

3D-printed molds can be seamlessly integrated into existing production lines. This minimizes transition times and optimizes overall production.

What are the latest technological developments in 3D printing?

The latest developments include improved machine performance. There are also new printing technologies. They enable higher speeds and better surface qualities, especially for metal and ceramic printers.

How does 3D printing contribute to sustainability?

3D printing can reduce the ecological footprint. It uses recyclable materials and bio-based plastics. The additive approach greatly reduces waste.

What are the challenges of using 3D-printed molds?

Technical challenges are accuracy and post-processing. The long-term stability of the molds is also important. This can be improved through material research.

What does the future of 3D printing in tool manufacturing look like?

The future of 3D printing in tool manufacturing looks bright. 3D-printed molds are becoming increasingly important. Advances in materials and technologies are enabling new applications.