Cavities play a major role in injection molding. They are important for costs and efficiency. We show you how to determine the correct number.

There are tried and tested methods and new ideas. These help companies to become better. New technologies and trends are also presented.

Important findings

- The number of cavities directly influences the production costs.

- Optimizing production efficiency through proper planning.

- Proven methods are essential for success in injection molding.

- Technological developments bring new opportunities.

- Quality assurance plays a decisive role.

Introduction to injection molding

The introduction of injection molding is important for many new products in plastics processing. Injection molding can be used to produce complex parts accurately and repeatably. It is ideal for mass production.

In injection molding, liquid plastic is injected into a mold. It then cools and hardens. This creates the desired part. Companies use it to reduce costs and work more efficiently.

The injection molding process is important for product development. It makes it possible to create complex shapes. You can find more information in our article on injection molded parts.

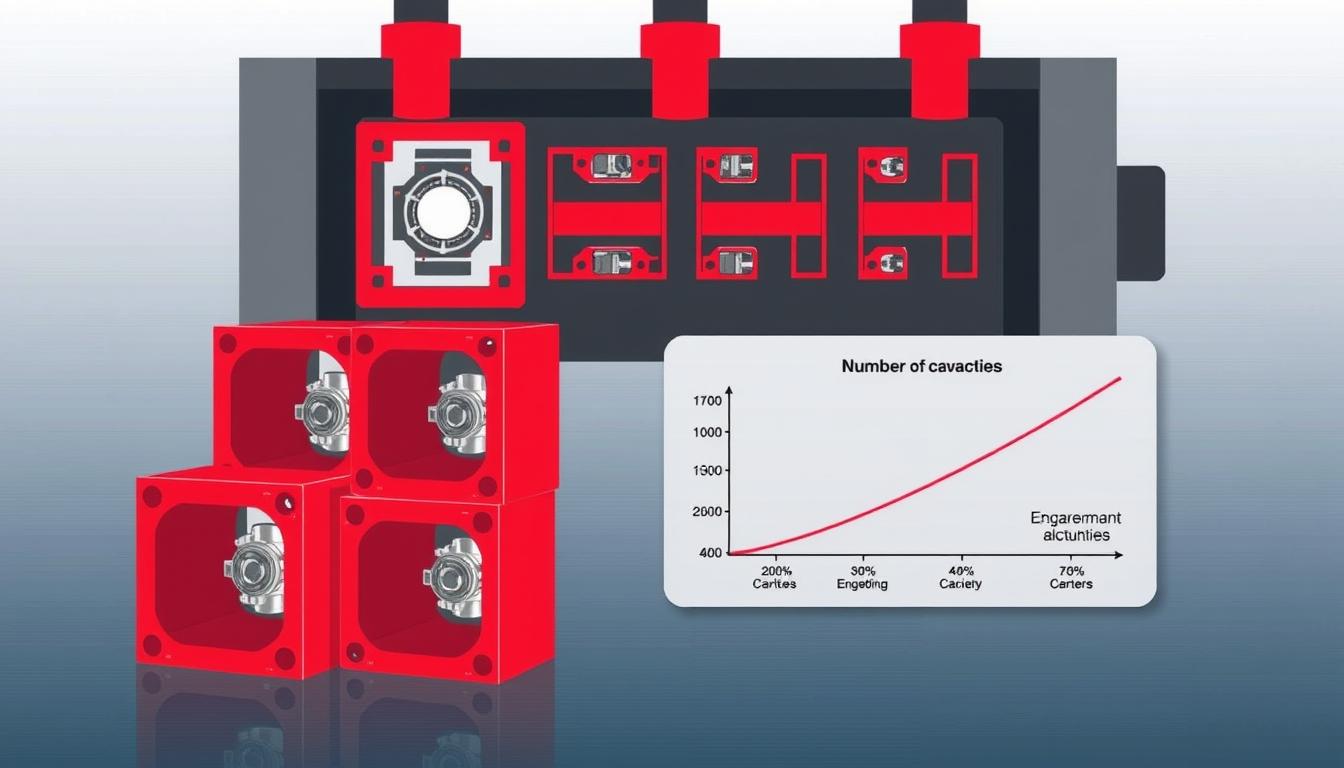

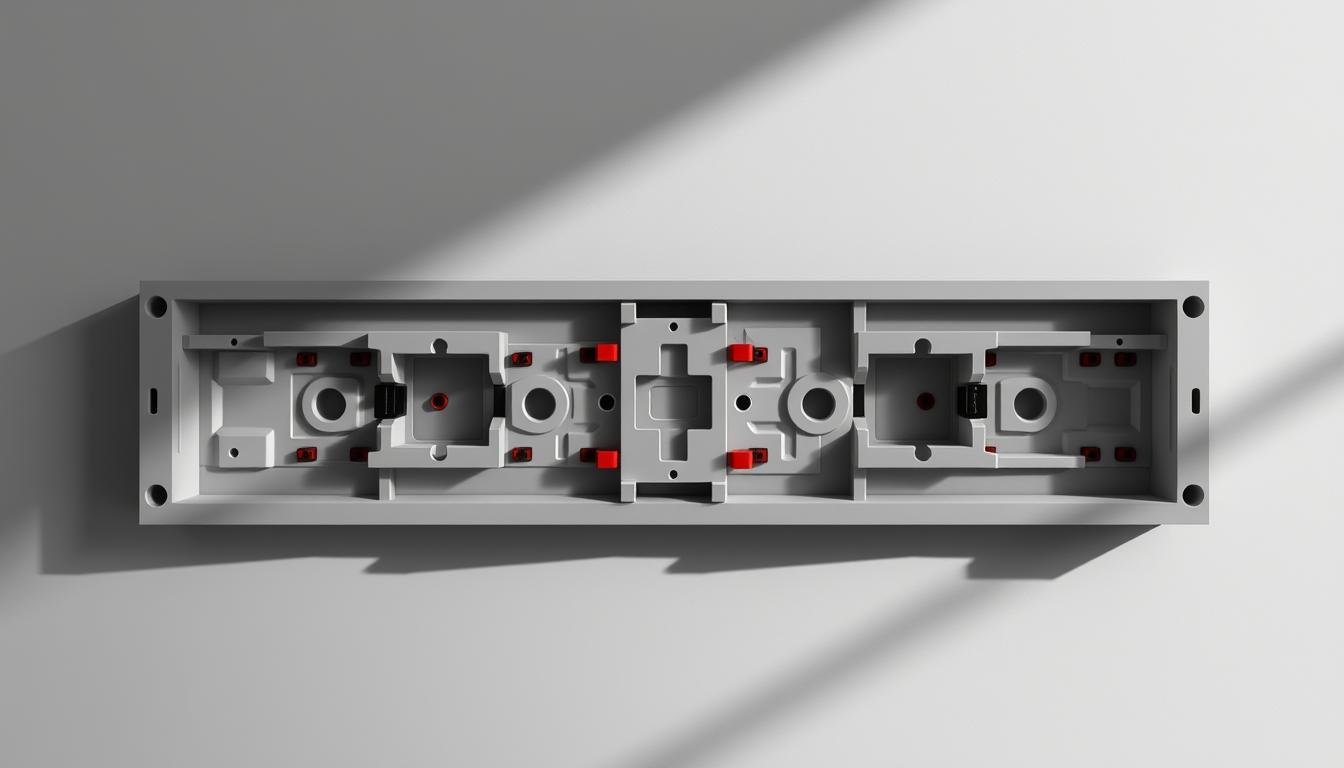

What are cavities in injection molding?

Cavities in injection molding are important hollow spaces in injection molds. The material is filled into these spaces. The definition of cavities refers to all shapes and sizes required for precise parts.

The number of cavities influences how many parts can be produced per cycle. More cavities mean more parts per cycle.

The exact positioning and size of the cavities is crucial when designing the mold. They ensure even filling and prevent overfilling or underfilling. Careful planning of the cavities improves efficiency and quality.

For more information about cavities in injection molding visit this website. There you will find detailed information.

The importance of the number of cavities

The number of cavities is very important for the efficiency of the injection molding process. One major advantage is that production costs can be reduced. If the mold and machines are a good fit, companies can save a lot.

More cavities not only mean lower costs. They also make production more efficient. Producing more parts at the same time increases productivity and reduces time.

It is important to weigh up the number of cavities, costs and efficiency. Manufacturers need to find out how they can reduce costs. That way, they remain competitive and can increase their market share.

| Number of cavities | Production costs (USD/part) | Efficiency increase (%) |

|---|---|---|

| 1 | 100 | 0 |

| 4 | 75 | 25 |

| 8 | 50 | 50 |

| 16 | 40 | 60 |

The analysis shows that clever cavity planning not only saves costs. It also increases efficiency. A good decision on the number of cavities is therefore very important for injection molding manufacturers.

Criteria for determining the optimum number of cavities

Choosing the right number of cavities is very important in injection molding production. There are many factors to consider. These include material requirements, costs and production times.

Material requirements and costs

Der Materialbedarf beeinflusst die Kosten eines Projekts stark. Bei weniger Kavitäten muss man oft mehr Material verwenden. Das kann die Kosten erhöhen.

A precise analysis of the material helps to find the best solution. You can find more information on costs and materials on this page.

Production times and efficiency

Production efficiency is also very important. More cavities can extend production times. This is especially true if the machines are not designed for this.

A company must carefully consider the impact of these factors. Careful consideration helps to avoid bottlenecks and increase efficiency.

Cavities in injection molding: economic number & best practice

The number of cavities in injection molding is very important. It influences the costs and times for production. Clever planning of cavities can reduce costs and improve quality.

There are proven techniques for injection molding. These techniques advise adjusting the number of cavities according to the project and quantity. There are many factors to consider:

- Material requirements and costs

- Production times

- Cost analysis

The right number of cavities is very important in injection molding. Optimization technologies help to make products more attractive. Efficient processes save resources and adapt quickly to the market.

Cavity planning should be done carefully. With proven methods, companies can improve their production and remain competitive.

Best practice examples for cavity planning

We will show you some examples of successful cavity planning. These experiences come from various projects. Companies have improved a lot by choosing the right cavities.

Through careful planning, they were able to increase their efficiency and profit. Such examples show how important a good strategy is.

Case study: Successful projects

A lot has happened in some projects. One manufacturer of consumer goods, for example, has reduced its costs. It adapted the number of cavities to its products.

He also used modern machines and improved designs. This made the production process much more efficient.

Error prevention in cavity planning

Avoiding errors is very important. The problem often lies in the wrong number of cavities. This can be expensive and time-consuming.

Regular checks and adjustments help to prevent problems. Companies should train their employees. This will help them avoid typical mistakes.

Technological developments in injection molding

New technologies are changing injection molding dramatically. They make it possible to create more cavities in molds without increasing costs. These advances are improving efficiency in plastics processing.

New materials are revolutionizing the design process. For example, 3D printing technologies are shortening production times enormously. They also increase flexibility in design.

The advantages of new technologies in injection molding are clear. They reduce production costs and increase product quality.

The role of quality assurance

Quality assurance is very important in the injection molding process. It helps to ensure the quality of the parts. Various measuring methods and standards ensure that everything is accurate.

Measurement methods and standards

Accuracy is very important in injection molding. Geometric measurement technology and optical processes help here. International standards ensure high quality and detect errors at an early stage.

Quality control in production

Quality control is very important during production. It ensures that all requirements are met. Regular checks keep rejects to a minimum.

Modern technologies help to monitor everything precisely. For more information on increasing efficiency, visit here.

FAQ

What are cavities in injection molding?

Cavities are hollow spaces in injection molds. Molten plastic is injected into them. The number of cavities influences production capacity and costs.

How does the number of cavities affect production costs?

More cavities can reduce the cost per part. This is because more parts can be produced at the same time. But the mold and machines have to fit.

What are the decisive criteria for determining the optimum number of cavities?

Material requirements, costs and production times are important. The efficiency of the machine also plays a role.

What technological developments are there in injection molding?

New developments include better machines and molding technology. There are also new materials and 3D printing technologies. These are revolutionizing mould design.

How is quality assurance ensured in injection molding?

Quality assurance is carried out using specific measuring methods and standards. There are also constant quality controls during production.

What are best practice examples for cavity planning?

Successful projects show how smart cavity selection can improve efficiency and profitability. They also help to avoid common mistakes.