In the world of plastics processing, we present the GIT/WIT technology. This technology, also known as gas and water injection molding, is very advanced. We, as experts, develop precise solutions for various industries.

Our aim is to offer high-quality injection molding processes. These processes are not only technically advanced, but also tailored to the needs of our customers.

We offer efficient and cost-saving solutions thanks to our technical expertise. Our production solutions are fast and effective. They meet the latest standards.

Discover how GIT/WIT technology can improve your product development. You can find more information in our article on manufacturing solutions.

Key findings

- GIT/WIT technology enables precise injection molding.

- Increasing efficiency in plastics processing.

- Reduction of material costs through innovative processes.

- Expert knowledge ensures individual production solutions.

- Fast, automated processes improve production.

Introduction to GIT/WIT technology

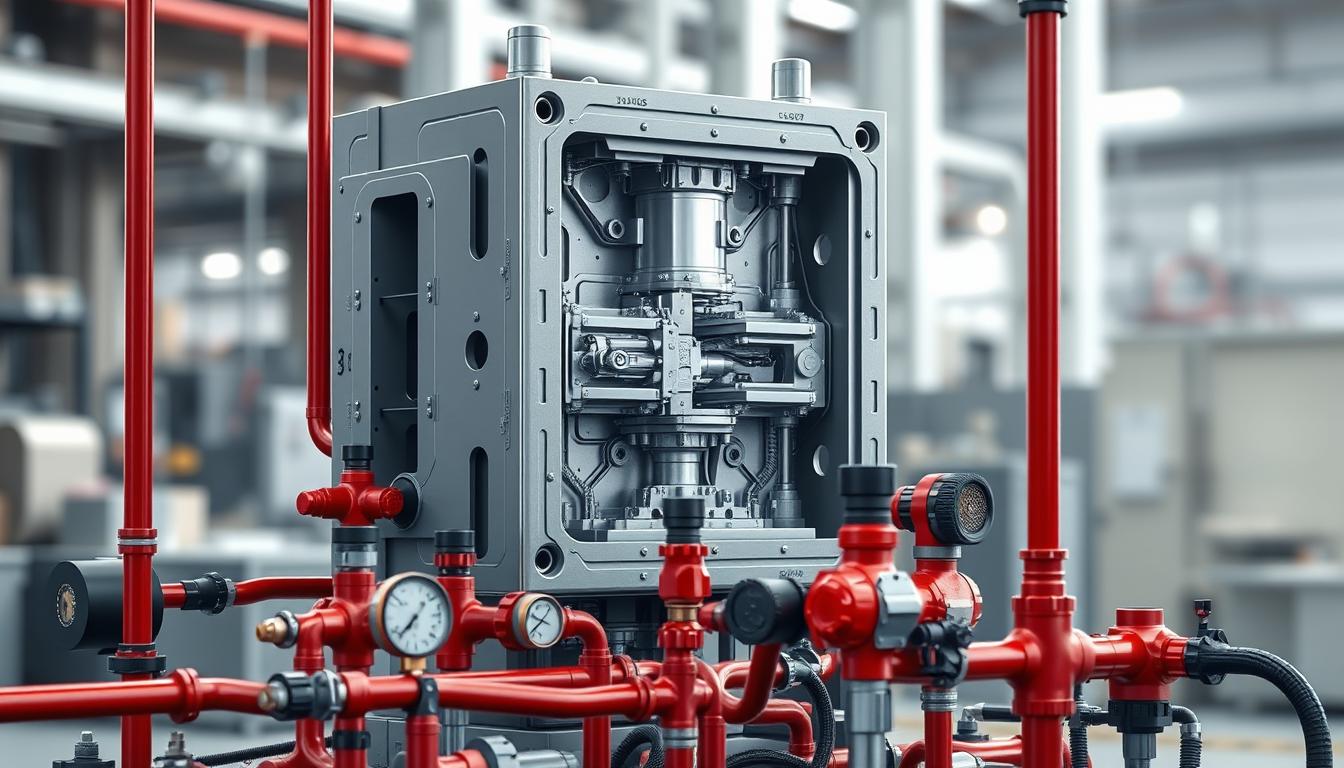

GIT/WIT technology is a major advance in injection molding technology. It combines internal gas and water pressure. This opens up new possibilities in the production of plastic parts.

This technology specifically creates air and water channels in plastic. This makes the components lighter and more stable.

GIT/WIT technology is very versatile. Many manufacturers choose it because of its advantages in processing and development. An introduction shows how valuable it is for the modern manufacturing process.

Manufacturers who use GIT/WIT have advantages such as faster throughput times and greater efficiency. This leads to cost reductions and better products. It shows how important it is to get to grips with the latest technologies in injection molding.

Advantages of gas and water injection molding (GIT/WIT)

GIT/WIT technology is changing the production process. It helps companies to work more efficiently and save costs. These advantages are particularly important in the B2B sector.

Increasing efficiency in the production process

GIT/WIT technology makes the injection molding process more efficient. It uses internal gas and water pressure to improve production. This allows components to be produced faster and without compromising on quality.

Companies benefit from shorter production times. They can produce more without losing quality.

Reduction of material costs

A major advantage of GIT/WIT is the reduction in material costs. Targeted technology can greatly reduce material consumption. This minimizes waste and promotes sustainability.

Companies that use GIT/WIT save costs. They make better use of their resources and optimize their production costs.

How GIT/WIT technology works

The GIT/WIT technology uses an injection molding process. It combines gas and water vapor. First, plastic is injected into a mold.

Gas or water vapor is then used. This technique creates cavities and cross-linked structures in the product.

This process reduces the weight of the product. It also saves material without losing strength. The production technique improves efficiency and cost control.

Companies that use GIT/WIT benefit enormously. You get a reliable and modern production method.

Application areas of GIT/WIT technology

GIT/WIT technology is popular in many industries. It offers innovative and efficient solutions. It is particularly valuable in plastics processing and the electrical industry.

Plastics processing in the automotive industry

GIT/WIT is very important in the automotive industry. It helps in the production of light, strong and stable plastic parts. This reduces costs and increases efficiency.

This enables new vehicles to appear more quickly. It also contributes to sustainability. The advantages are:

- Increased production speed

- Reduced post-processing requirements

- Improved surface quality

Use in the electrical and electronics industry

In the electrical industry, GIT/WIT is used for complex electronic components. It enables precise shapes and high quantities. This is very attractive for manufacturers.

This technology increases efficiency and accuracy. It is ideal for high-quality components in the digital world. The most important points are:

- Optimization of the component architecture

- Reduction of waste material

- Increasing product service life

Quality features of GIT/WIT technology

GIT/WIT technology improves injection molding quality enormously. Its production standards ensure consistent success.

A key feature is the precise pressure control. This control ensures even material distribution and reduces air pockets. This results in parts with a great surface and little post-processing.

The technology can be flexibly adapted. This means customers can get exactly what they need. Modern technology monitors quality at every stage. This guarantees that all parts meet the highest manufacturing standards.

The choice of materials is also crucial.Materials with optimum properties increase injection molding quality.Even with complex shapes and designs.This results in products that are effective and durable.

Gas and water injection molding (GIT/WIT): A detailed overview

The GIT/WIT process has many special technical features. These make it interesting for many industries. It uses gas or water as a pressure medium, which improves production.

Technical features of the process

The special features of the GIT/WIT process are:

- Increased flexibility in shaping

- Optimization of machine running times

- Reduction of post-processing costs

The process can implement complex shapes well. This results in high-quality end products. It is also economical, which appeals to many companies.

Comparison with conventional injection molding processes

GIT/WIT is convincing in comparison to injection molding. It is faster and cheaper than traditional methods. It enables:

- Lower material consumption

- Faster cycle times

- Fewer rejects and material losses

These advantages increase profitability. It helps to avoid unexpected costs. For more information visit our website about PMMA application tips in injection molding.

Training and further education for GIT/WIT experts

Training and further education are very important for companies that specialize in GIT/WIT technologies. These programs help to train specialists. They learn how best to use these new technologies.

Our training covers many topics, such as technical aspects and safety. Our experts provide practical knowledge. This can be applied immediately at work.

Through training, your skilled workers grow and production processes become more efficient. Further training helps you to familiarize yourself with new technologies. For example, with CO2 in GIT applications. You can find more information in our article on internal gas pressure technology.

Investieren Sie in die Weiterbildung Ihrer Fachkräfte. So stärken Sie die Qualität und Wettbewerbsfähigkeit Ihres Unternehmens. Eine gute Ausbildung hilft, Herausforderungen in der modernen Produktion zu meistern.

Economic benefits for companies through GIT/WIT

GIT/WIT technology brings many advantages for companies. It helps to reduce costs and earn more. In the plastics industry, it improves efficiency and quality.

Profitability and long-term savings

Profitability is important for success. GIT/WIT reduces production costs. It enables more precise control and better material utilization.

- More precise control over the manufacturing processes

- Reduction of rejects and rework

- Increasing production efficiency

Cost reductions bring long-term benefits. Investments in GIT/WIT often bring quick returns. Statistics show significant improvements.

GIT/WIT technology is revolutionizing plastics processing.It contributes to economic stability.Investments in this technology improve quality and profitability.

Trends and developments in GIT/WIT technology

GIT/WIT technology is constantly evolving. There is a trend towards greater efficiency and sustainability in production. Engineers and developers are working to improve production processes and reduce costs.

Artificial intelligence is becoming increasingly important in GIT/WIT technology. It helps to identify and solve problems at an early stage. This improves quality and reduces downtime.

There is also a focus on environmentally friendly materials. Manufacturers want to use more recyclable and less harmful plastics. This will make the industry more sustainable.

| Trend | Development | Future prospects |

|---|---|---|

| Integration of | KIOptimization of production processes | Improved efficiency, fewer rejects |

| Sustainable materials | ncreasing the proportion of recyclable plastics More | environmentally friendly production processes |

| Digital networking | Implementation of IoT technologies | Intelligent networked manufacturing systems |

The future of GIT/WIT technology looks promising. New ideas are constantly improving the industry. Companies can thus set themselves apart from the competition.

Conclusion

GIT/WIT technology offers great advantages in industry and design. It makes the production process more efficient and saves material costs. This makes it an important tool for modern manufacturers.

This technology helps companies to hold their own against the competition. It makes it possible to constantly find new solutions. This makes the future more sustainable.

Investments in GIT/WIT technology are good for the future. They make it possible to keep up with other competitors. The constant further development shows how important this technology is.

To find out more about GIT/WIT technology, visit our website. There you can find out how you can improve your production: Discover GIT/WIT technology. We help you look to the future.

FAQ

Was ist GIT/WIT-Technologie?

GIT/WIT technology is a method of manufacturing plastic components. Air and water channels are introduced into the material. This results in lighter and more stable parts.

What are the advantages of GIT/WIT technology?

It makes the production process more efficient and saves material costs. It also makes it possible to manufacture lighter products without losing strength.

In which industries is GIT/WIT technology used?

It is used in the automotive, electrical and electronics industries. Its versatility makes it very popular.

How does the GIT/WIT process work?

First, plastic is injected into a mold. Internal gas or water pressure is then applied. This creates cavities in the product.

Which quality features are important for GIT/WIT technology?

High precision, material efficiency and innovative technologies are important. These increase the product service life.

Does your company offer training for GIT/WIT?

Yes, we offer special training courses. They are designed to equip specialists with the necessary knowledge.

Ja, wir bieten spezielle Schulungskurse an. Sie sollen Fachleute mit dem nötigen Wissen ausstatten.

It offers long-term savings and efficient use of resources. This is very beneficial for companies.

What does the future of GIT/WIT technology look like?

It is constantly evolving. New possibilities are constantly being discovered through innovation and technical progress.