XXL 3D printing large format service

- First XXL parts in record time

- size up to 1200 x 1200 x 1200 mm

- instant offer

- All 3D printing manufacturing processes

- small and large series at the best price

- industrial quality

- First parts in a few days

- TOP 3D printing company

- offer in a few hours

Send data & receive 3D printing price by email

All uploads are confidential & encrypted. Privacy policy

Over 200+ companies

trust maxnext

XXL 3D printing: Why maxnext

Cost-effective & fast. Whether simple 3D components or complex, large-format assemblies in XXL 3D printing.

Fast, personal communication and best price directly in the first offer.

small series and large series

3D printing / small and large series. We accompany you!

Fast and results-oriented

Maxnext is the 3D printing service provider with experience. We accompany you from prototype to market launch & series production. The result is scalable and high-quality products for your company’s success.

We find the most economical solution for every project. From development to series production. From simple components to complex assemblies.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex components from the 3D printer

- The partner for strong brands

- offer in a few hours

- Personal Expert

- Production-oriented design adjustments

- SLA, SLS, FDM and many more

XXL 3D printing, i.e. printing very large objects, can be difficult for several reasons:

1. Scaling: 3D printing builds an object layer by layer. The larger the object, the more layers are needed. However, scaling from small to large objects can pose challenges. Printing time can be very long, and there is a risk of deformation or warping during the printing process.

2. Machine size: XXL 3D printing requires special printers capable of printing large objects. Such printers are more expensive and less common than standard 3D printers for smaller objects. The size and weight of the printing machine can also cause logistical problems in setting up and running it.

3. Materials: Selecting suitable materials for XXL 3D printing can be challenging. Not all materials are suitable for printing large objects as they may not have the required mechanical properties or may not behave well during the printing process. Developing materials suitable for XXL printing requires additional research and development.

4. Structural stability: Large objects often have more complex structures and are more prone to deformation and instability. Proper design and support structures are critical to ensure that the printed object maintains its shape and is structurally stable.

5. Cost: XXL 3D printing can be expensive due to the specialized equipment and materials required. Scaling up the printing process can also lead to higher operating costs due to the need for more material and longer printing times.

Although XXL 3D printing is technically challenging, advances in technology are constantly being made to overcome these challenges. As materials, printing techniques and machines evolve, XXL 3D printing is becoming more accessible and effective.

A collaboration with maxnext on XXL 3D printing+ can offer several advantages:

1. Expertise in XXL 3D printing: Maxnext specializes in XXL 3D printing and has extensive knowledge and experience in this field. They may have developed advanced printing technologies and equipment that allow large and complex objects to be manufactured precisely and efficiently.

2. Scalability: XXL 3D printing allows you to produce objects of impressive size that would not be possible with conventional printing methods. A collaboration with maxnext could enable you to produce such large-scale objects, be it for industrial applications, architectural models, works of art or other purposes.

3. Cost efficiency: The use of XXL 3D printing can reduce costs compared to traditional manufacturing methods. Since maxnext is specialized in this field, they may be able to offer solutions to optimize manufacturing costs and enable economical production of large objects.

4. Individuality and adaptability: XXL 3D printing allows the production of unique and customized products. By working with maxnext, you could turn your ideas and designs into reality and receive products tailored specifically to your requirements.

5. Innovation potential: XXL 3D printing is an emerging field with great innovation potential. A collaboration with maxnext could give you access to new technologies, materials and printing processes that could give you a competitive advantage and help you develop innovative solutions.

It is important to consider individual needs and requirements before entering into a collaboration. A detailed conversation with maxnext about your specific requirements and expectations could help you determine whether a collaboration makes sense.

The stability of 3D printed parts can depend on several factors, including the material used, the printing parameters, and the design of the part itself. In principle, 3D printed parts can have sufficient stability and strength to meet certain applications, but there are some considerations to keep in mind:

1. Material selection: Various materials can be used for 3D printing, including plastics, metals, ceramics and composites. Each material has different mechanical properties and stability. Metallic 3D printed parts can usually have higher stability than plastics.

2. Printing parameters: The settings in 3D printing, such as printing speed, layer thickness and infill density, can affect the stability of the printed component. Optimally setting these parameters can lead to more stable results.

3. Component design: A well-designed component with appropriate wall thicknesses, fasteners and structural features can improve stability. Adding reinforcements or ribs can increase structural integrity.

It is important to note that 3D printed parts do not typically have the same strength as traditionally manufactured parts. However, they can be sufficient for many applications, especially when designed correctly and used with specific requirements in mind.

When it comes to critical applications, such as aerospace or medical, rigorous testing and certification procedures must be carried out to ensure the stability and reliability of 3D printed components.

certifications

… we have that too. In our factory near Augsburg we work according to DIN ISO without being certified. That saves money.

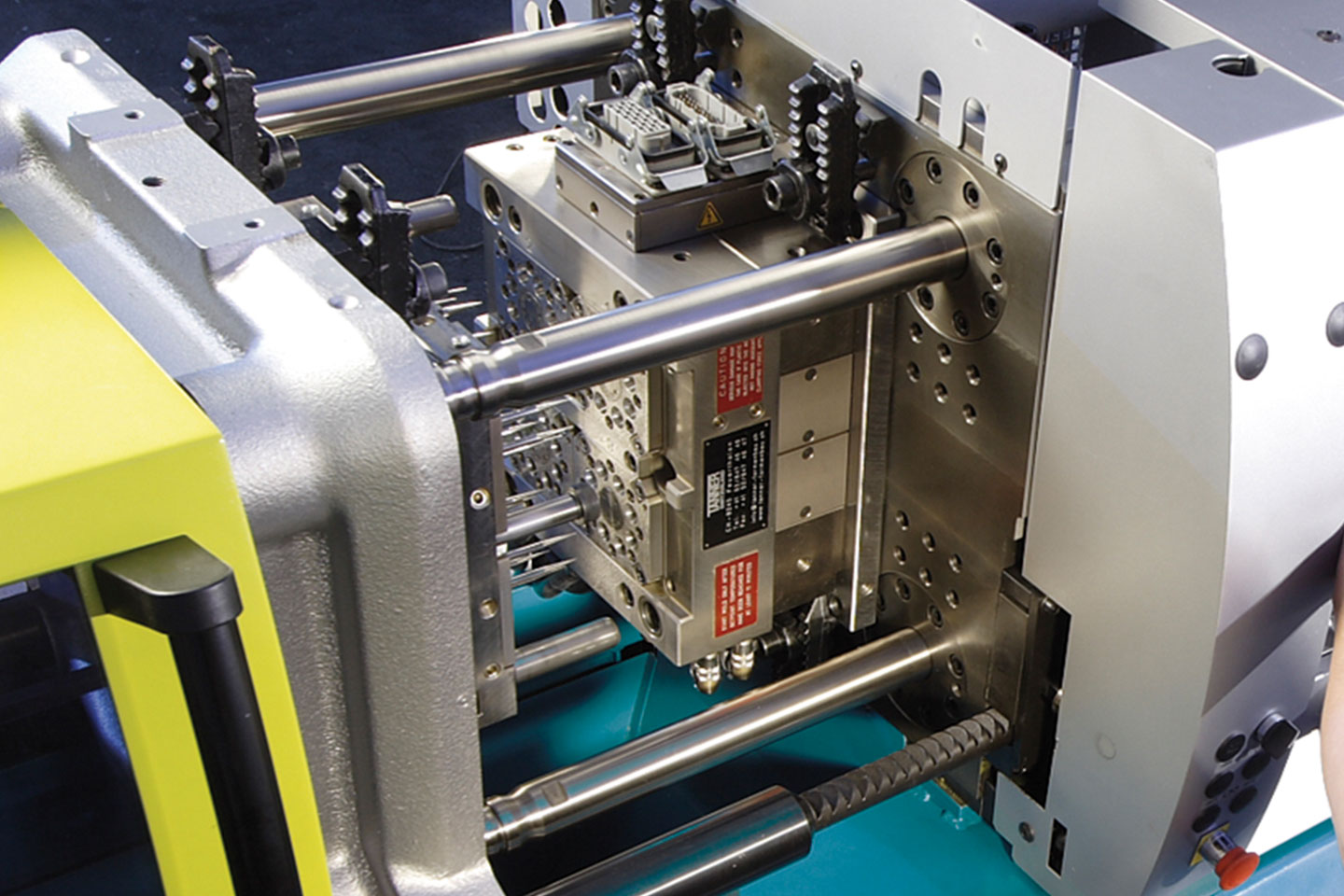

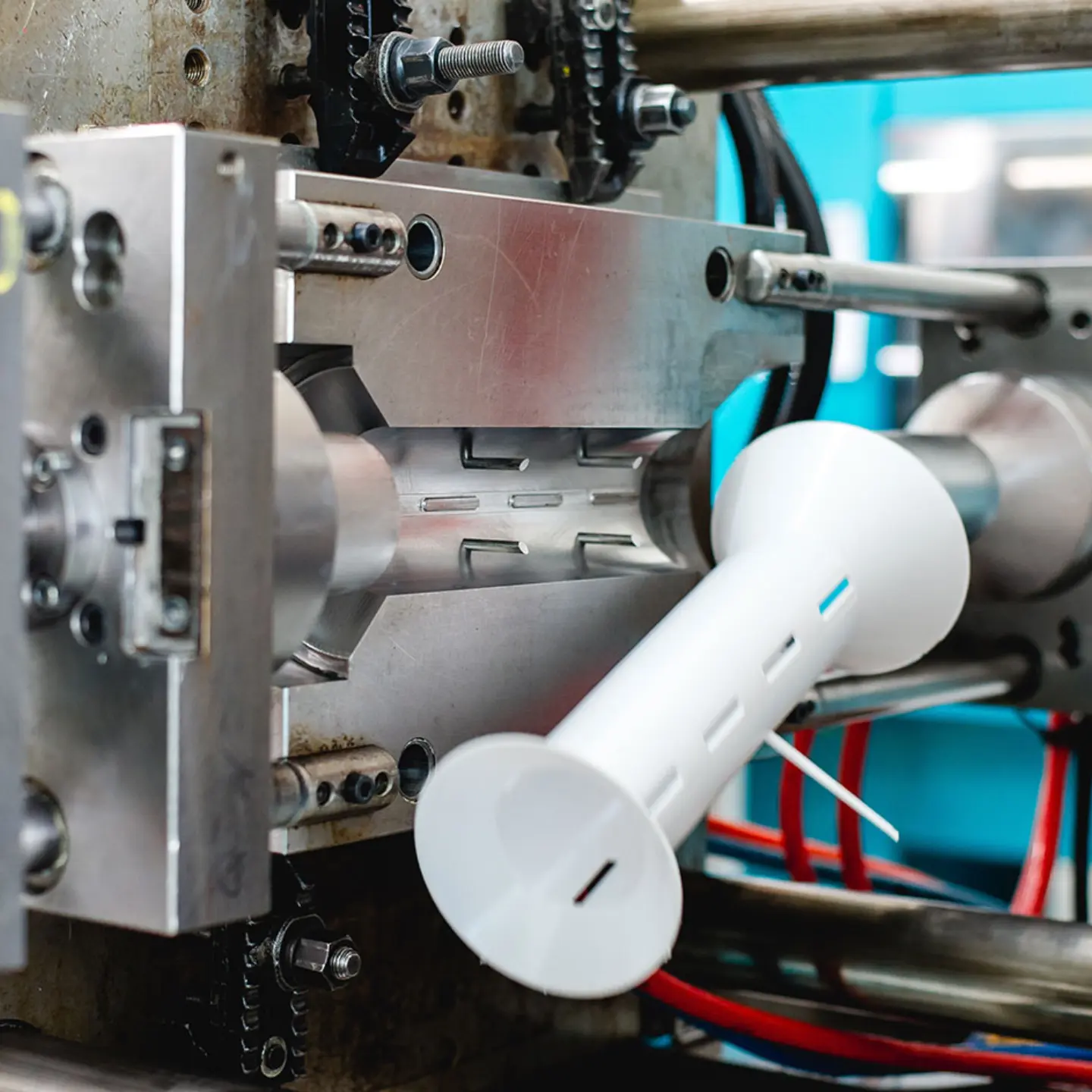

Our injection moulding plant near Nuremberg is certified to DIN ISO 9001 & 14001: ideal for anyone who values this.

Frequently Asked Questions

Sure! Write an email with your idea and we will design / construct your product for the perfect 3D printing.

It's very simple: Send us your 3D data and we will create a suitable best price offer for you in a short time.

We send the finished precision 3D parts within a short time with a tracking ID.

In short:

Product development, 3D printing/prototyping, mold making & series production under one roof. This guarantees short routes. The competitive advantage for fast market launches.

Right across the board: from A for automotive to Z for pet supplies. Whether simple components or complex technical assemblies made from high-performance plastics.

Experience from over 25 years of plastic processing guarantees the best results for your project. Request a quote now!

It depends on the following factors:

- plastic used

- weight of the component

- complexity of the component

- purchase quantity

Send us your details now for an offer in a few minutes

Yes, that is important to us! You will get a personal contact for development / design & production