Multi-component injection molding 2K and 3K - order easily online

- First multi-component parts in just a few days

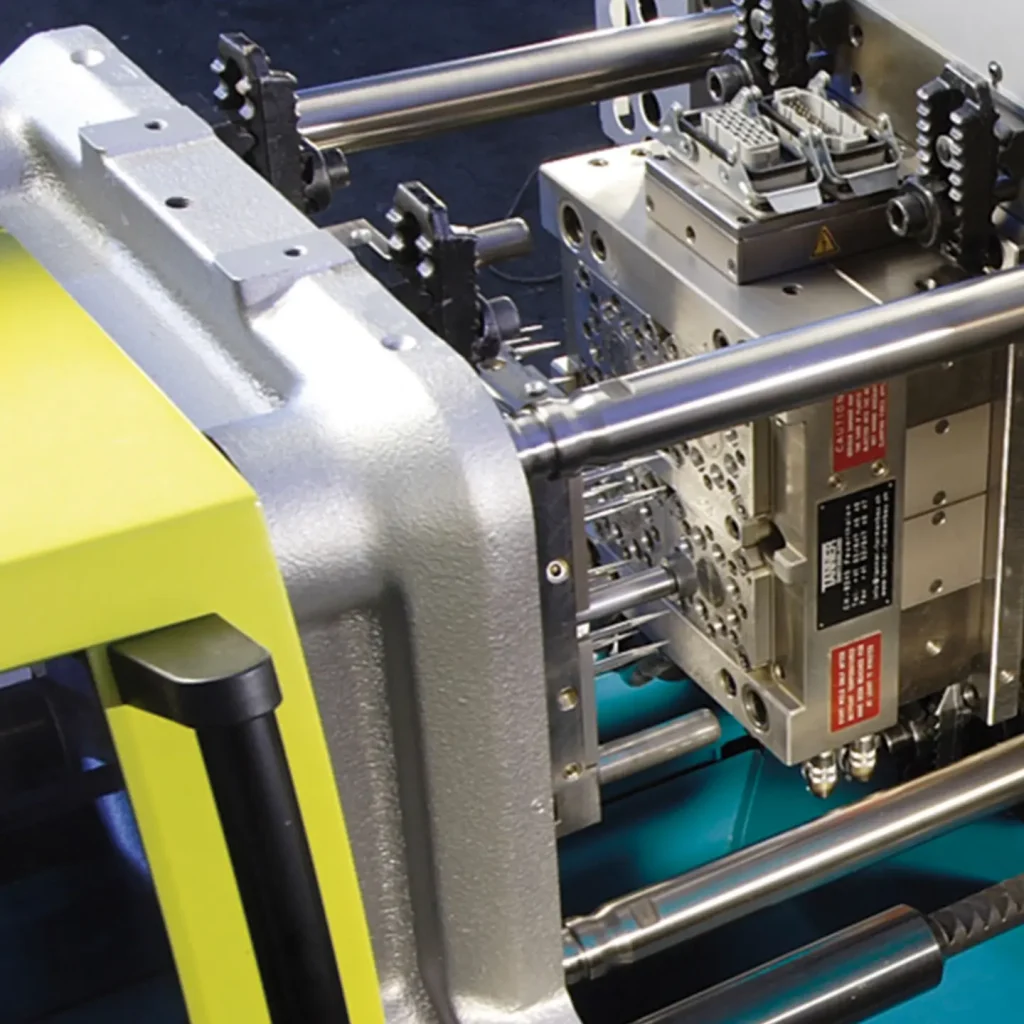

- In-house mold making

- offer in a few hours

- First parts in a few days

- In-house mold making

- offer in a few hours

Over 200+ companies

trust maxnext

Why maxnext?

Multi-component injection molding for precisely fitting components. Ideal for the integration of seals and the creation of high-quality surfaces.

Fast, personal communication and best price directly in the first offer.

small and large series

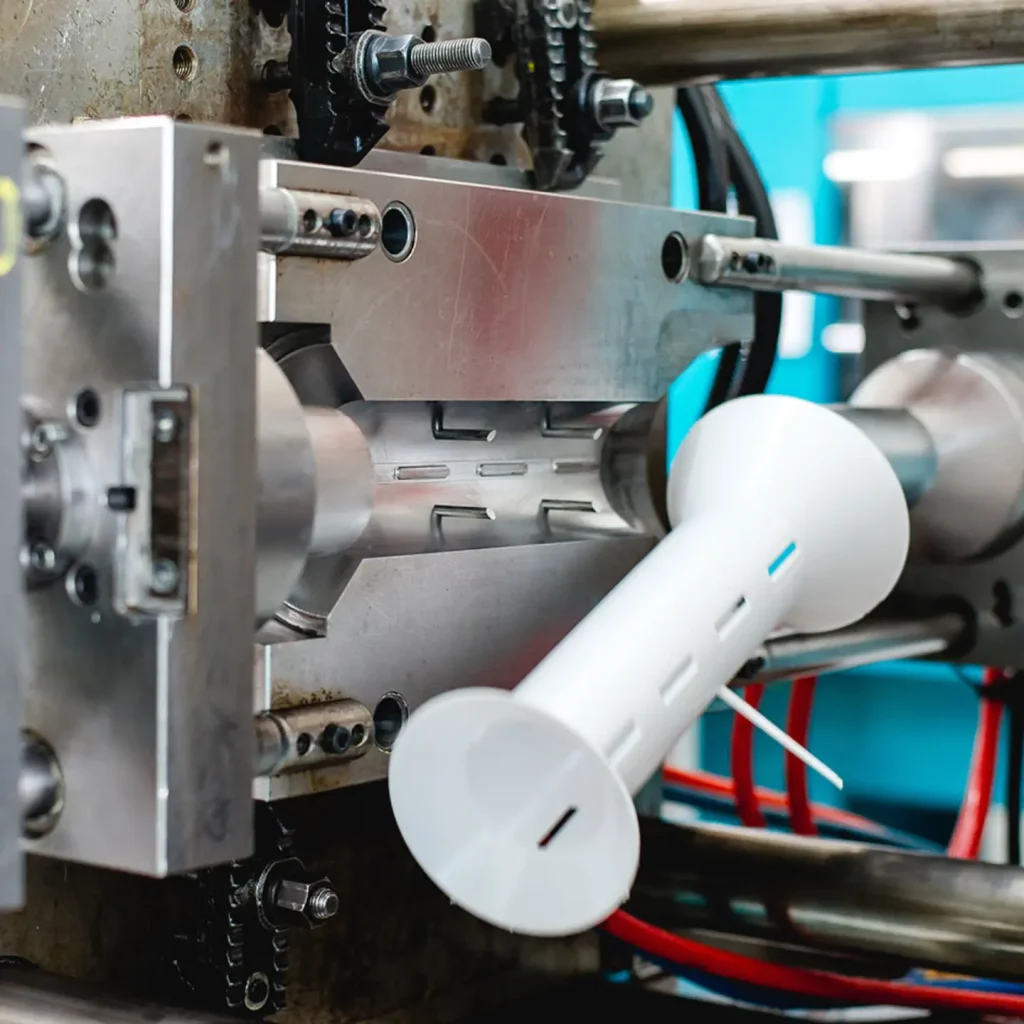

Multi-component injection molding: 2K and 3K directly from the manufacturer

1+1 = 1

We put together what belongs together. We combine different plastics in just one step.

We will find the most economical solution for your project. From development to series production of 2K components. From simple surfaces to overmolding of inserts.

Let’s get it started!

Winfried Zangerle

CEO @ germanhotspot.de

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex 2K injection molded parts

- The partner for strong brands

- offer in a few hours

2k and 3K injection molded parts

We manufacture composite plastic parts according to your requirements from a wide range of thermoplastics, such as ABS, PET, POM, PC, PA, PP, PS, PEEK and other engineering plastics.

As one of the few plastic injection molding plants, we ourselves produce larger assemblies that are assembled from individual parts.

certifications

… we have that too. In our factory near Augsburg we work according to DIN ISO without being certified. That saves money.

Our injection moulding plant near Nuremberg is certified to DIN ISO 9001 & 14001: ideal for anyone who values this.

Frequently Asked Questions

Sure! Send us an email with your idea and we will design/construct the product.

It's very simple: Send us your 3D data and we will create a suitable best price offer in a short time.

We send the injection-molded parts with a tracking ID. This way, you always know where your plastic components are.

In short:

Product development, mold making & manufacturing under one roof. This guarantees short routes. Not only does this save you money, but it also makes you independent of long & fragile supply chains.

Right across the board: from A for automotive to Z for pet supplies. Whether simple components or complex technical assemblies made of high-performance plastics.

Over 25 years of experience in 2K & 3K injection molding guarantees the best results for your project. Request a quote now!

It depends on the following factors:

- plastic used

- weight of the component

- complexity of the injection-molded part

- purchase quantity

The biggest factor is the production of the injection molding tool. However, once this has been built, the subsequent investments are low. The more components are ordered, the cheaper they can be produced in series.

Example calculation:

Yes, that is important to us! You will get a personal contact for the production of your components.

We accompany you in our state-of-the-art injection molding shop from development to series production.