About maxnext

Manufacturing Experts

We help engineering teams move from prototype to series production with certified plastic manufacturing around the globe

How we apply Digital Manufacturing 4.0

Engineering first

Every project is reviewed with manufacturability, cost efficiency, and scalability in mind.

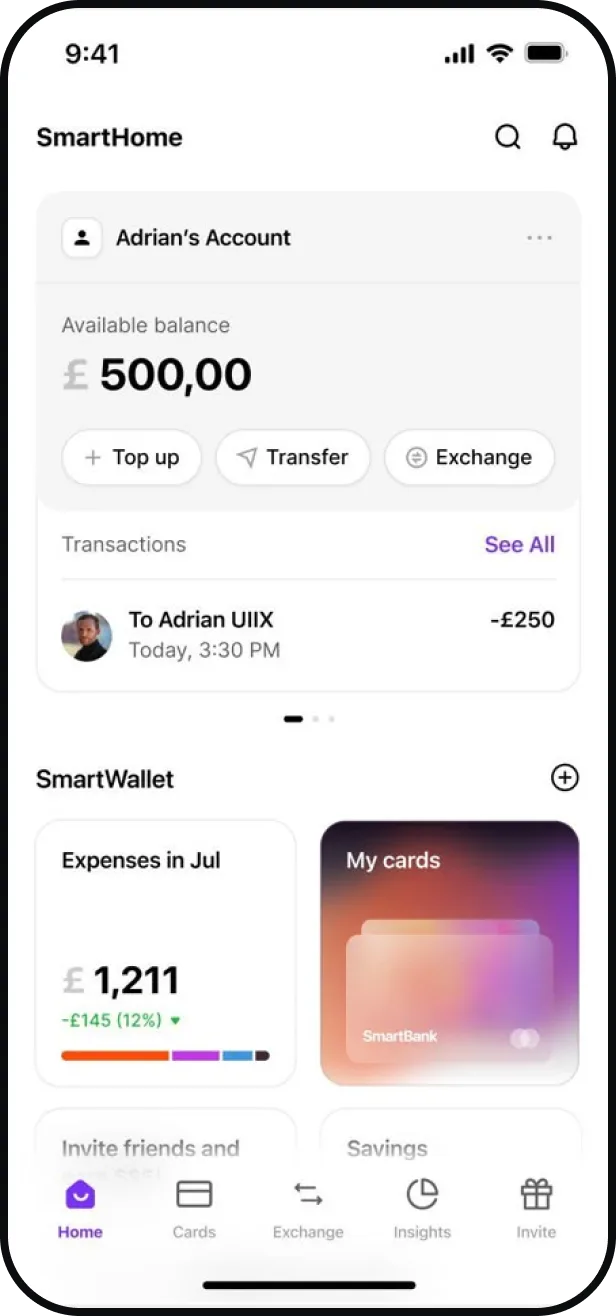

Digital workflows

Automated quoting, DFM checks, and transparent communication throughout the entire process

Production-ready mindset

From prototype to series production without changing suppliers or processes

Free global capacities. Faster production. Lower cost

We use a global network of free manufacturing capacities and match each project with the best fitting expert based on technical requirements

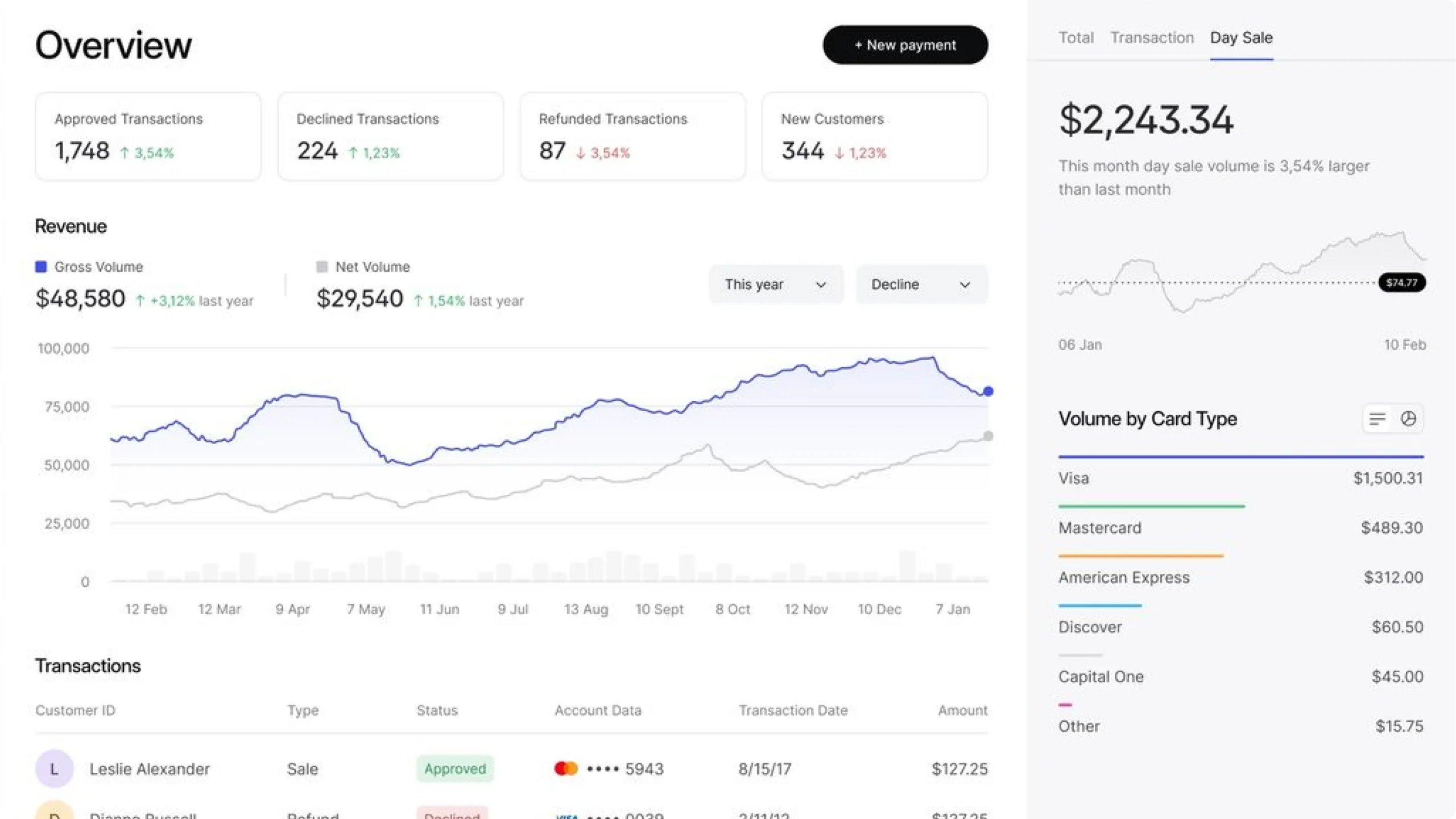

Everything under control with NextDesk

From quotation to production and delivery, every project is managed and tracked in our internal platform NextDesk, ensuring transparency, control, and clear communication at every step

Who we are

Germany

Headquarters

Advanced Toolmaking

In-house tool shop & maintenance

CNC machining (3–5 axis), EDM, grinding

Worldwide Production Options

Full DFM support included

Quality is built into every step

Certified processes and engineering control ensuring consistent production quality

Standards & Compliance

All production processes follow DIN and ISO standards, supported by certified quality management systems

Inspection & Measurement

Dimensional inspection, material verification and process monitoring ensure every part meets defined specifications

Documentation & Traceability

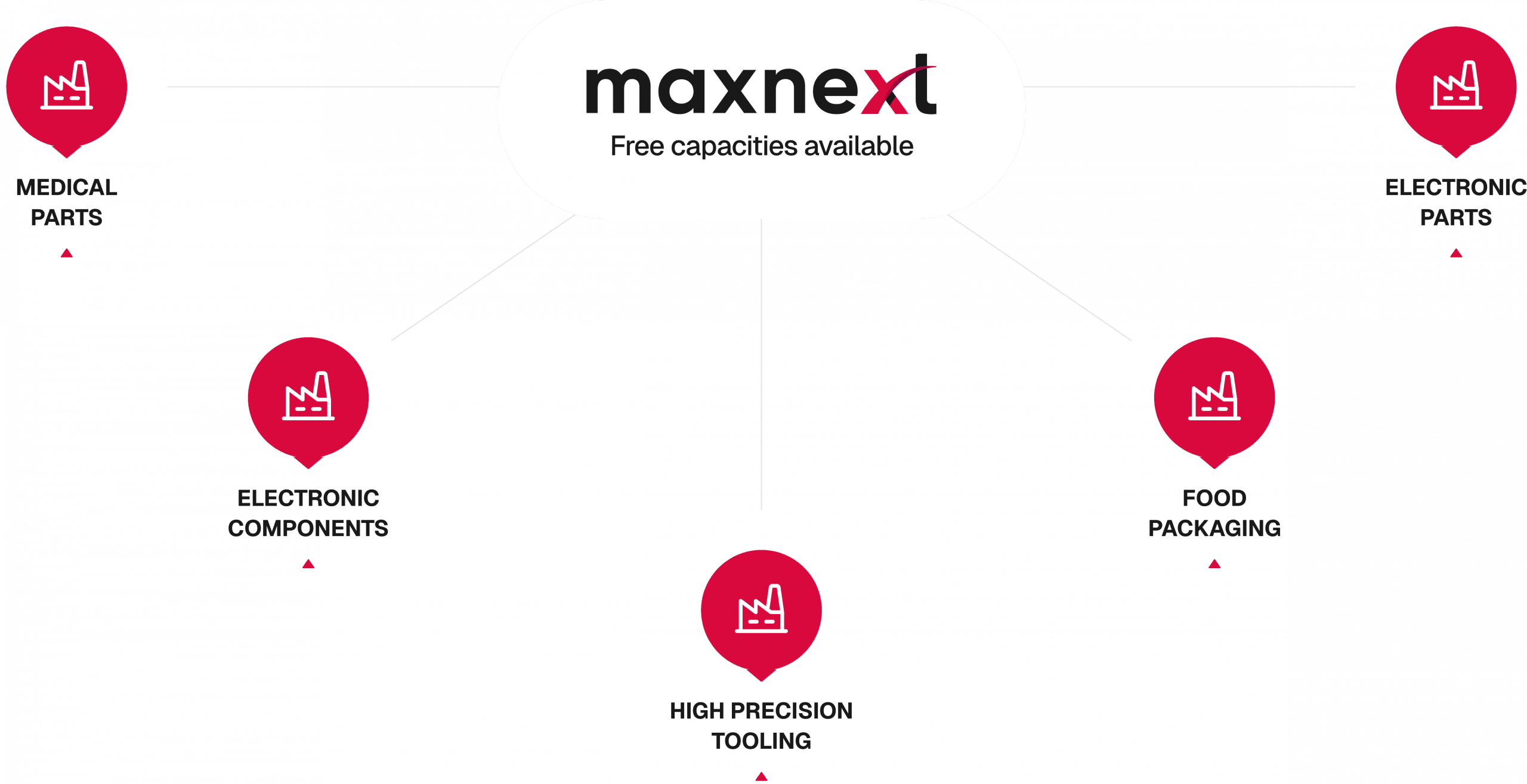

What we manufacture

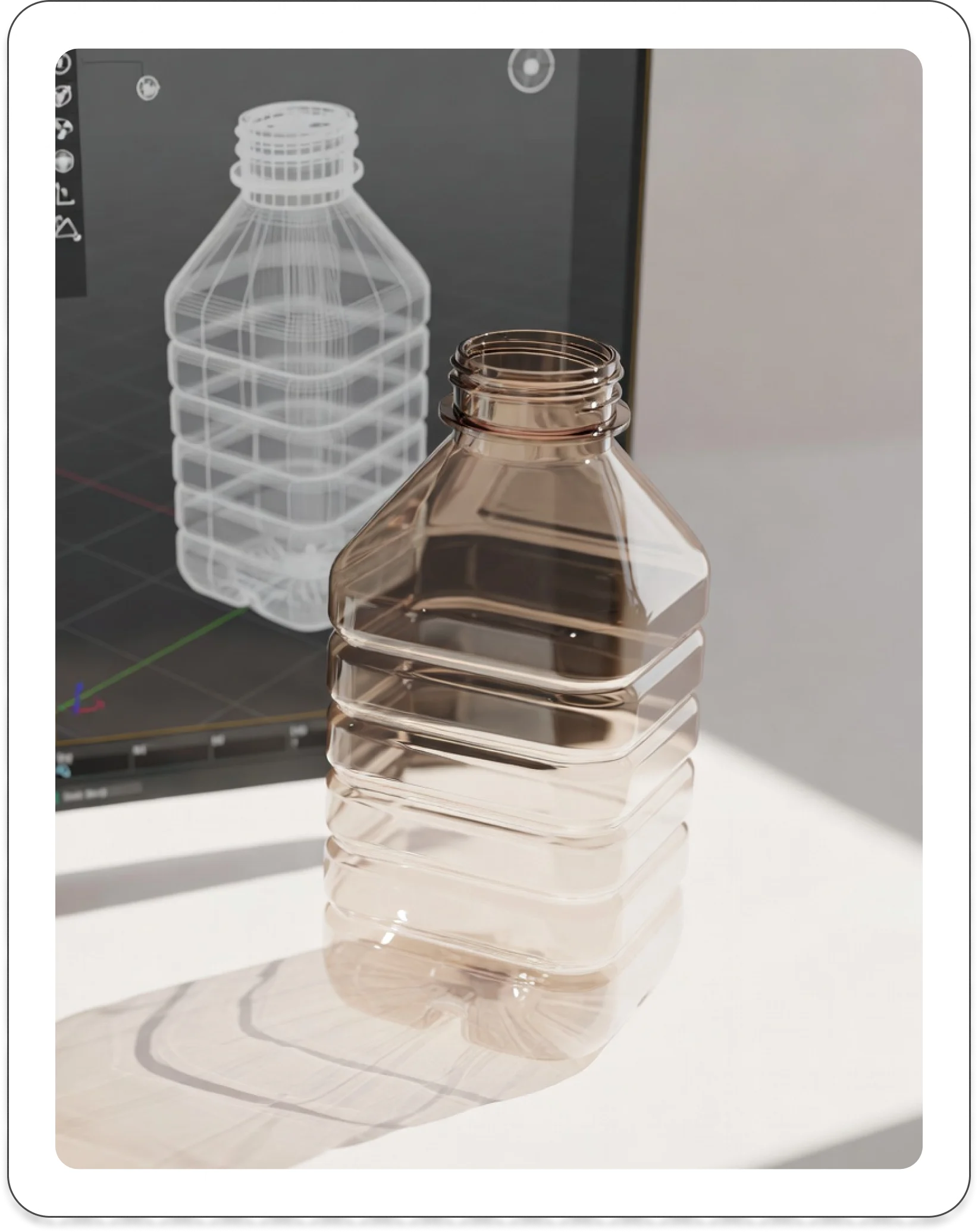

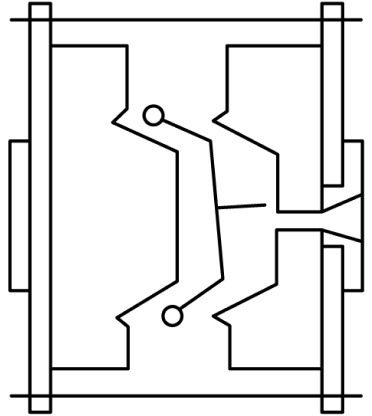

Injection Molding

- Small to large series production

- Wide range of technical plastics and reinforced materials

- Tight tolerances and DIN-compliant quality standards

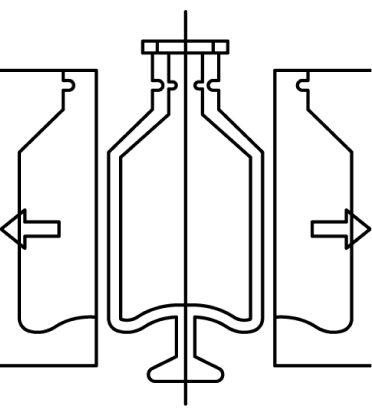

Blow Molding

- Hollow plastic parts for technical applications

- From pre-series to large-volume production

- In-house tooling and process expertise

Need expert support for injection or blow molding solutions?