CNC machining

- First parts in a few days

- 3-axis and 5-axis machining

- offer in record time

- First parts in a few days

- 3-axis and 5-axis machining

- offer in a few hours

Over 200+ companies

trust maxnext

Why maxnext?

The dream of every buyer & entrepreneur. Whether simple components or complex assemblies – anything is possible with CNC machining!

Fast, personal communication and best price directly in the first offer.

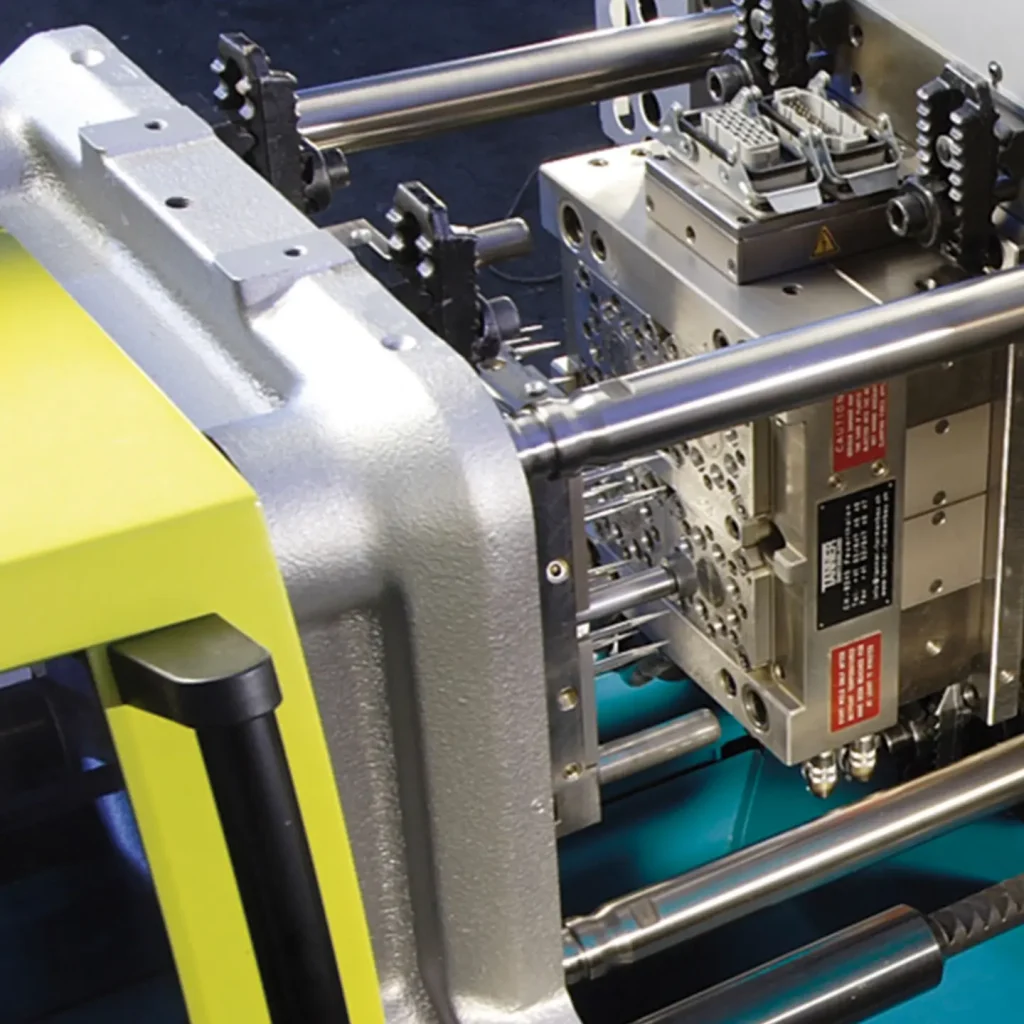

Reliable and efficient CNC machining services

Fast & easy!

Maxnext is the brand maker of KSE Kunststoff. If you are looking for a reliable and efficient CNC machining process for the production of complex parts, maxnext is the right place for you.

We find the most economical solution for every project. From development to series production. From simple components to complex assemblies.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex parts

- The partner for strong brands

- offer in a few hours

-

CNC manufacturing of prototypes

-

CNC manufacturing of special parts

-

CNC manufacturing of finished products

-

CNC small and large series

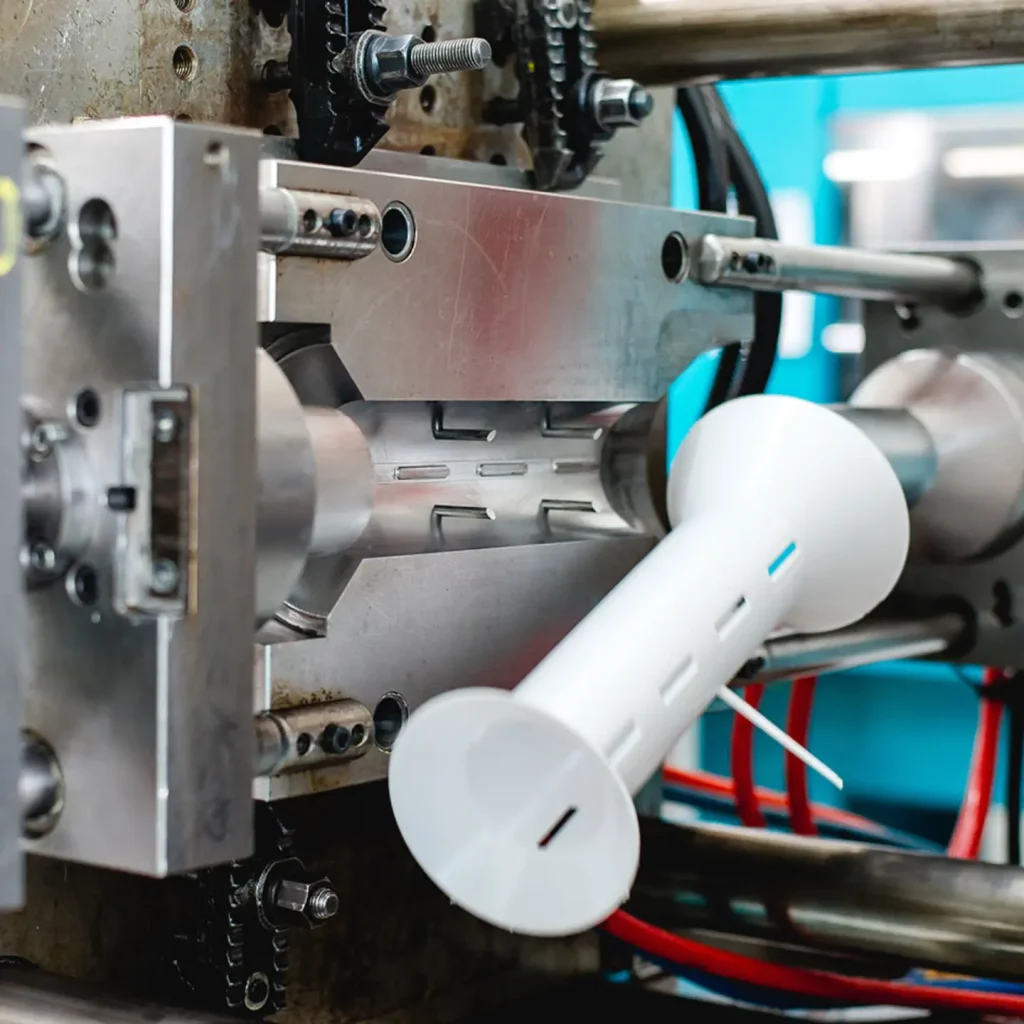

In the world of product development, time is of the essence. The faster a prototype can be produced, the sooner it can be used in the development process. With traditional manufacturing methods, creating a prototype can be a time-consuming and costly endeavor. However, with CNC manufacturing, it is possible to produce a prototype quickly and inexpensively. CNC machines are computer-controlled, which means they can create complex shapes with precision and repeatability. This makes them ideal for producing prototypes, which often require tight tolerances and intricate geometries. Additionally, CNC manufacturing is typically faster than traditional methods, allowing prototypes to be produced within a matter of days or even hours. Therefore, CNC manufacturing is an essential tool for the product development process.

There are many factors to consider when developing prototypes. You want to make sure you have an experienced and knowledgeable team and a CNC machining center that is up to the task. At maxnext, you get both. We have a state-of-the-art CNC machining center that is capable of handling any prototype development project, big or small. But more importantly, we have a team of experts ready to assist you every step of the way. We'll help you develop your prototype and then oversee the production process to make sure everything goes to plan. So if you're looking for a stress-free prototype development experience, look no further than maxnext.

CNC machining is a great way to produce special parts for your project. At maxnext, we take advantage of the benefits of CNC machining when producing special parts. In addition, we have a personal contact for the production of your special parts. We will guide you from prototype development to series production in our CNC machining center. This way, you can be sure that your project will be completed on time and within budget. In addition, we offer our customers a wide range of services including engineering, design and manufacturing. We are confident that we can meet your needs and exceed your expectations. Contact us today to learn more about our CNC services and how we can help you with your next project.

welding plastic parts

We offer the optimal welding process for all common plastics with our plastic welders trained according to DVS 2281.

- hot gas welding,

- Heating element butt welding and

- ultrasonic welding

cover all possible requirements in our plastics sector. Unlike alternative methods such as riveting or screwing, welded joints ensure liquid- or gas-tight seams with a mostly smooth, flawless surface without notch effect. Depending on the process, this result can be refined to the maximum. Some joints of individual components require a particularly even distribution of stress, which leads to highly resilient results with the appropriate plastic welding method. We can even manufacture larger assemblies without any problem.

At maxnext, we offer CNC machining services for small and large-scale production. We have a wide range of CNC machines that allow us to handle virtually any machining project you have. In addition, we have a team of highly skilled and experienced CNC machinists who can operate our machines to produce parts that meet your exact specifications. And best of all, we provide you with personal support throughout the entire process, from development to mass production.

Maxnext offers a wide range of CNC machining services that can be tailored to your specific needs. We have a team of experienced engineers who will work with you to develop the best manufacturing solution for your project. Whether you need a small batch of parts or high volume production, we have the capacity to meet your requirements. In addition, we provide you with a personal contact for each project, so you can be assured that your parts will be manufactured to the highest standards. With our state-of-the-art equipment and skilled staff, we can provide you with the highest quality CNC machined parts in the shortest time possible. So if you need CNC machining services, maxnext is the perfect choice. Contact us today to find out more about our CNC machining services.

certifications

… we have that too. In our factory near Augsburg we work according to DIN ISO without being certified. That saves money.

Our injection moulding plant near Nuremberg is certified to DIN ISO 9001 & 14001: ideal for anyone who values this.

Frequently Asked Questions

Sure! We know that not all companies have access to 3D data, so we offer a range of 3D data creation services. Email us with your idea and we will design/engineer your product.

It's very simple: Send us your 3D data and we will create a suitable best price offer for you in a short time.

We send the finished parts with a tracking ID. This way you always know where your components are.

In short:

Product development, mold making & manufacturing under one roof. This guarantees short routes. Not only does this save you money, but you are also independent of long and fragile supply chains.

Right across the board: from A for automotive to Z for pet supplies. Whether simple components or complex technical assemblies made from high-performance plastics.

Our extensive and extensive experience from over 25 years guarantees the best results for your project. Request a quote now!

It depends on the following factors:

- Material used

- weight of the component

- complexity of the part

- purchase quantity

Yes, that is important to us! You will get a personal contact for the production of your parts.

We accompany you in our state-of-the-art CNC machining center from development to series production.