small series in 3D printing

- First parts in record time

- TOP 3D printing service providers

- instant offer

- All 3D printing manufacturing processes

- industrial quality

- First parts in a few days

- TOP 3D printing company

- offer in a few hours

- SLS / SLA / FDM and much more

Over 200+ companies

trust maxnext

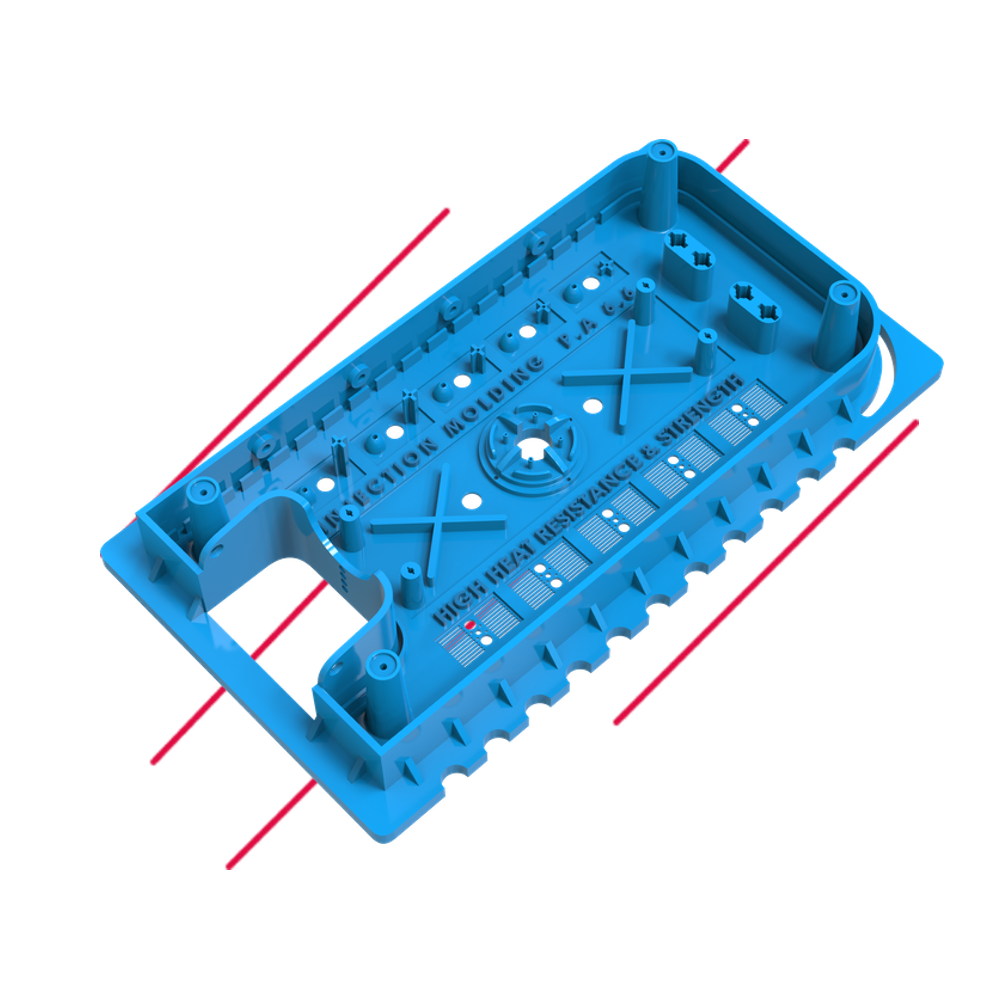

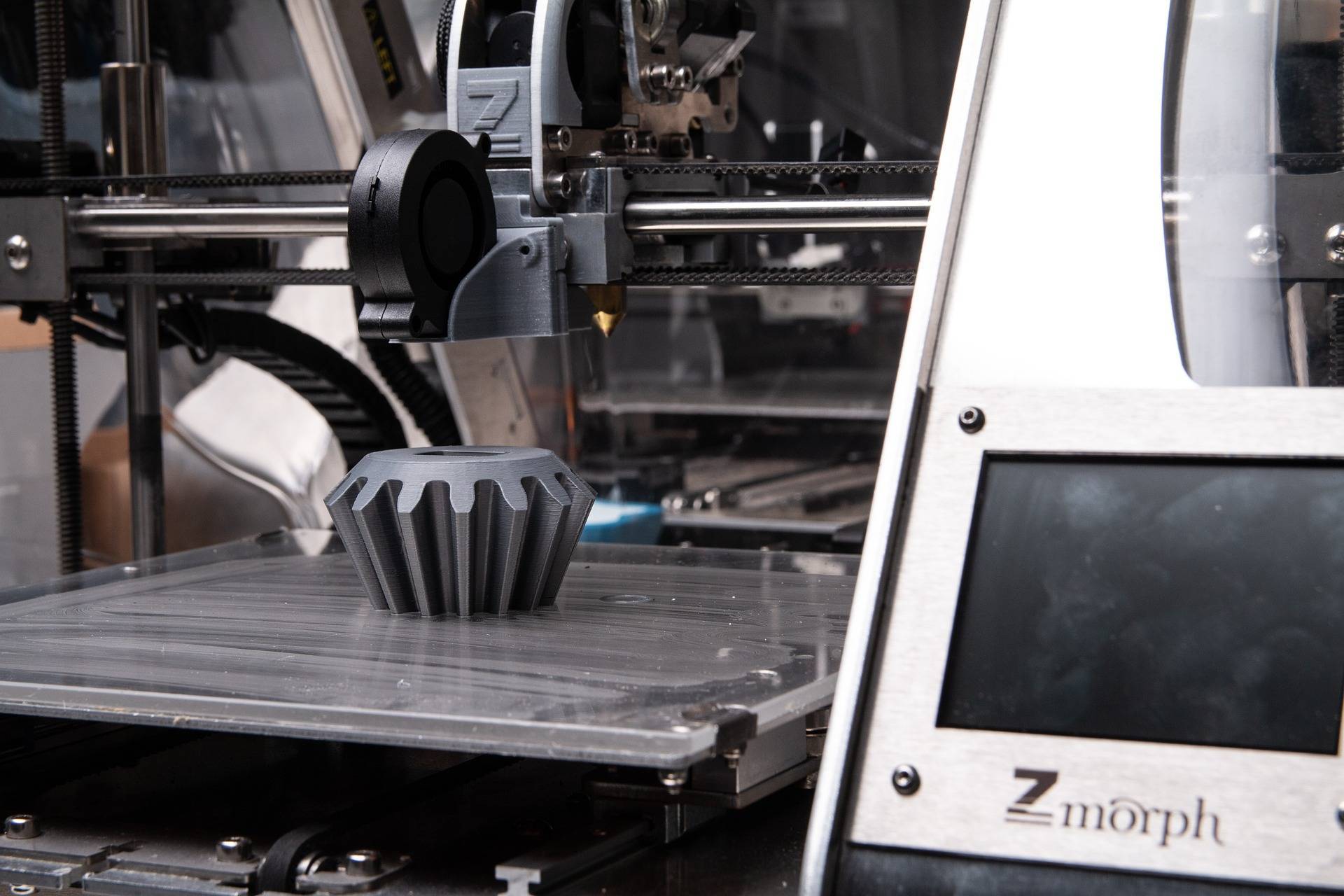

Small series in 3D printing by maxnext

Fast and cost-effective – Whether you need simple 3D parts or complex assemblies, we offer fast 3D printing services at competitive prices.

We value personal and fast communication and guarantee the best price in the first offer.

Starting from 1 piece

3D printing / small and large series. We accompany you!

Fast and results-oriented

Maxnext has extensive experience as a 3D printing service provider and supports you throughout the entire process, from prototyping to market launch and series production. Our goal is to produce scalable and high-quality products that contribute to your company’s success.

Our focus is on finding the most economical solution for each project, from development through to series production. Whether it’s simple components or complex assemblies, we offer customised solutions to ensure you achieve the best possible result.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex components from the 3D printer

- The partner for strong brands

- offer in a few hours

- Personal Expert

Rapid prototyping:

Multi-material 3D printing allows multi-colored parts to be produced quickly and cost-effectively. Flexible materials can also be combined, for example for the integration of seals in housings. This enables rapid iteration and testing of prototypes before they are produced on a larger scale.

Cost efficiency: Multi-colour 3D printing can be cost-effective as it allows parts to be produced in smaller quantities and without expensive tooling.

Complex geometries: Multi-colour 3D printing can be used to produce parts with complex geometries that would be difficult or impossible using conventional manufacturing methods. Different materials can also be combined in this way.

Experimental design: 3D printing of different filaments enables designers and engineers to quickly and cost-effectively create and test experimental designs to explore new ideas and concepts.

Ideal for use with electricity.

Perfect insulating properties & fire protection thanks to fiber reinforcement. More about flame retardants in plastics.

There are different types of surface finishes for 3D plastic parts. We offer:

-

Polishing: Polishing 3D plastic parts can create a smooth and shiny surface that improves the appearance of the final product.

-

Painting: Painting is a widely used method for surface finishing of plastic parts. A wide range of colours and effects can be achieved by painting.

-

Printing: Printing on 3D plastic parts enables high resolution, multiple colours and a wide range of designs.

-

Anodising: Anodising is a chemical process in which the surface of the plastic part is covered with an oxidised layer that makes it more resistant to corrosion and wear.

-

Staining: Staining is a chemical process in which the surface of the plastic part is treated with a solution that removes the surface to create a matt appearance.

-

Coating: Coating is a method in which the plastic part is coated with a thin layer of another material such as metal or rubber.

-

Blasting: Blasting 3D plastic parts with fine particles can create a matt, textured or rough surface.

Choosing the best surface finish depends on several factors, such as desired aesthetics, functionality and cost.

assembly & device construction

In the field of equipment construction, we manufacture functional and mechanical assemblies. To do this, we complete the plastic items produced for you with additional components such as circuit boards, switches, motors and cables, the purchase of which and the planning of which we are happy to take over for you. Final inspections, functional tests and serial number management are of course documented in a traceable manner.

Special requests and individual designs are possible at any time!

certifications

… we have that too. In our factory near Augsburg we work according to DIN ISO without being certified. That saves money.

In unserem Spritzgusswerk bei Nürnberg sind wir zertifiziert nach DIN ISO 9001 & 14001: Ideal für alle, die darauf wert legen.

Frequently Asked Questions

Sure! Write an email with your idea and we will design / construct your product for the perfect 3D printing.

It's very simple: Send us your 3D data and we will create a suitable best price offer for you in a short time.

We send the finished precision 3D parts within a short time with a tracking ID.

In short:

Product development, 3D printing/prototyping, mold making & series production under one roof. This guarantees short routes. The competitive advantage for fast market launches.

Right across the board: from A for automotive to Z for pet supplies. Whether simple components or complex technical assemblies made from high-performance plastics.

Experience from over 25 years of plastic processing guarantees the best results for your project. Request a quote now!

It depends on the following factors:

- plastic used

- weight of the component

- complexity of the component

- purchase quantity

Send us your details now for an offer in a few minutes

Yes, that is important to us! You will get a personal contact for development / design & production