Plastic lenses are very popular in the world of optical lenses. They impress with their quality and new technologies. We explain why these lenses are so important and how we manufacture them.

Our goal is to make your projects successful. We attach great importance to innovation and quality. Discover the world of optical lenses with us.

This will help you to make better decisions. For more information about plastic lenses, visit our article here.

Important points

- Plastic optical lenses offer high quality and innovation.

- Plastic lenses are resource-saving and versatile.

- Artificial intelligence optimizes manufacturing processes.

- Precise glasses for different applications are available.

- Precise glasses for different applications are available.

- Plastic lenses enable simple and cost-efficient production.

Introduction to plastic optical lenses

The world of plastic lenses opens new doors in modern optics. Plastic optical lenses are lightweight and shatterproof. This makes them perfect for many applications.

They are lighter and safer than glass lenses. That is a major advantage.

Environmentally friendly materials are being used more and more. This is how we protect the environment and make long-lasting products. These lenses are transparent, protect against UV radiation and come in many shapes and sizes.

The introduction to plastic lenses shows how the industry is growing. It offers innovative solutions for engineers and decision makers. We understand this exciting technology better.

Advantages of plastic optical lenses

Plastic optical lenses have many advantages. They are lightweight, which makes them comfortable to wear. They are also easier to work with than other materials.

One major advantage is their resistance to breakage. Compared to glass, they are more resistant to impact. This makes them safer for everyday use.

Another advantage is their cost efficiency. They are cheaper to produce. This helps companies to save costs and use them in large quantities.

Plastic lenses also have great optical properties. They are light and safe. They also protect the eyes better from UV radiation.

| Advantage | Description |

|---|---|

| Lightness | Comfortable and easy to handle |

| Lightness | Comfortable and easy to handle |

| Cost efficiency | Lower manufacturing costs enable wider applications |

| UV protection | Better protection for the eyes in medical applications |

Plastic optical lenses: application and areas of use

Plastic optical lenses are versatile and lightweight. They are used in many areas. The most common areas of application are

- Glasses and contact lenses for personal use

- Optical devices such as microscopes and telescopes

- Special accessories in photography, including lenses and filters

- Medical applications, e.g. in endoscopes and surgical instruments

- Technical applications in industry, such as sensors and measuring devices

The quality of the lenses is very important for medical applications. In medical technology, they improve vision and functionality. This helps to improve patient care.

In the field of optics, these lenses support the development of new diagnostic techniques.

Special materials and manufacturing processes are required in the industrial sector. For example, optical lenses made of plastic are resistant and flexible. This is particularly useful in demanding environments.

Materials and manufacturing processes

Materials and manufacturing processes are very important in the production of plastic optical lenses. High-quality materials ensure durability and functionality.

Special plastics such as polycarbonate and acrylic are often used. They are known for their clarity and impact resistance. The right choice of plastic is crucial for the lens properties.

Modern manufacturing processes use precise machines and automated procedures. These technologies enable error-free and efficient production. Digital milling and injection molding processes ensure precise shapes and material usage.

- Selection of suitable materials for the specific application requirements.

- Simulation and design of the lens shape using CAD software.

- Production of the lenses using advanced injection molding methods.

- Various post-processing steps to improve the surface quality.

Understanding the manufacturing processes increases efficiency and innovation in plastics production.

Plastic optical lenses - quality & innovation

Today, quality and innovation are very important for plastic optical lenses. We use modern technologies to get the best results. New processes and materials help us to produce clear and durable lenses.

Artificial intelligence is changing how we manufacture lenses. Automation makes the process more efficient and quality consistently high. Real-time monitoring ensures that we always maintain high standards.

Our innovation not only promotes data, but also sustainable solutions. By using the latest technologies, we remain at the forefront. Quality and innovation are our goal, and we want to see them in every product.

Technological advances in lens production

Technological advances in the manufacture of plastic optical lenses are fundamentally changing the industry. Digitalization is improving production processes. This significantly increases efficiency and quality.

AI enables intelligent systems to analyze data in real time. This enables them to produce lenses more precisely.

These advances bring many advantages:

- Faster production times

- Improved part quality

- Reduced production costs

One example of these technologies is the continuous compression molding (CCM) process. It is used in the CRoCoMold project. This is how high-quality optical plastic parts are produced.

Digitalization and AI are revolutionizing production lines. They enable flexible processes for specific customer requirements. The result is a customer-oriented manufacturing solution.

These achievements make companies pioneers in the industry. They create sustainable competitive advantages.

Developments in 3D printing technology demonstrate the diversity of modern manufacturing processes. 3D printing enables individual design and rapid prototype development. This is a great relief for companies.

Maintenance and care of plastic optical lenses

Proper care and maintenance are very important. They help to ensure that plastic optical lenses can be used for a long time. Regular cleaning and careful handling will keep the lenses in good condition for a long time.

To keep your lenses clear and functional, you should do the following:

- Use a microfiber cloth for cleaning to avoid scratches.

- Always store the lenses in a protective case to minimize external influences.

- Clean the lenses regularly with a suitable solution that is suitable for plastic.

- Avoid the use of harsh chemicals, as these can damage the surface of the lenses.

- Carry out a visual inspection to detect scratches or other damage at an early stage.

You should be careful when handling the lenses. Always grip the edges to avoid fingerprints. For more information on the care of plastic lenses, visit the page on extrusion tools.

You can ensure the longevity of your lenses by taking simple but effective steps for care and maintenance. This will keep them in top shape for years to come.

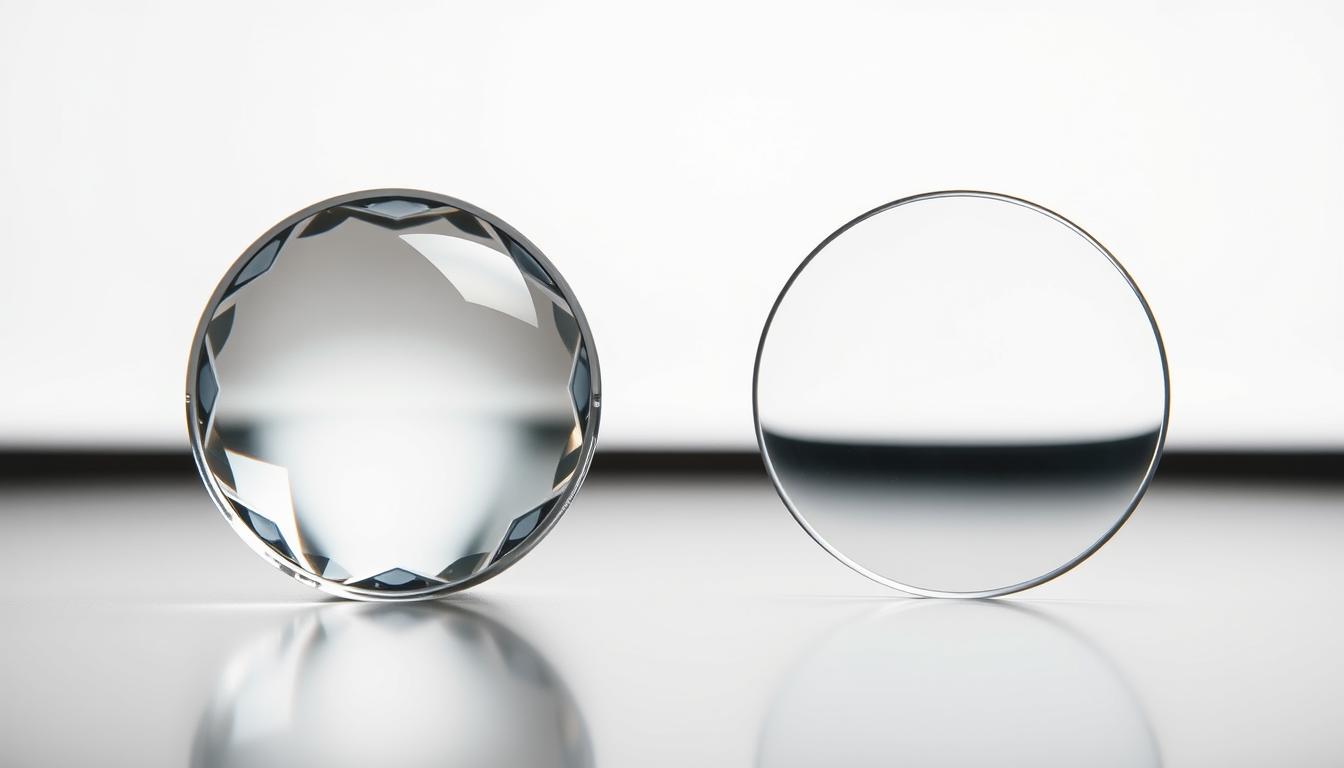

Comparison: plastic vs. glass

When comparing plastic and glass lenses, the differences quickly become apparent. Plastic lenses are flexible and robust. This makes them popular in many areas. They are lightweight, shatterproof and comfortable in everyday life.

Glass lenses shine with their clear optics and scratch resistance. They are ideal for high-quality photography or optical devices. The choice depends on the requirements and areas of application.

A precise comparison will help you make the best choice for your project. Plastic is versatile and easy to work with. Glass is more stable during temperature changes.

| Property | Plastic | Glass |

|---|---|---|

| Weight | Light | Heavy |

| Break resistance | High break resistance | More sensitive |

| Optical clarity | Very good | Excellent |

| Scratch resistance | Low | Very high |

| Processing | Easier | Difficult |

The right choice depends on knowing the advantages and disadvantages. Think about the requirements and desired features. This will help you make an informed decision.

Market overview and trends in the plastics industry

The plastics industry is constantly evolving. New trends are bringing innovative technologies and materials to the manufacture of optical lenses. Market analysis shows that consumers are looking for sustainable and high-quality products.

This influences the way in which products are manufactured. AI technologies are becoming increasingly important. They help to reduce costs and increase efficiency.

This is particularly beneficial for B2B customers and engineers. The demand for precise and customizable optical lenses is growing. This leads to more growth in the plastics industry.

Another trend is the focus on lightweight and durable materials. These meet the requirements of many applications. The market analysis also emphasizes the importance of environmentally friendly practices and recycling systems.

These measures help to reduce the industry’s ecological footprint.

The plastics industry is looking for new solutions to meet market needs. These developments offer exciting opportunities for companies and technical decision-makers.

Conclusion

In this summary, we discuss plastic lenses. They are lightweight, break-resistant and versatile. This makes them a good choice for many industries, such as optical, automotive and medical.

New technologies are improving the production of plastic lenses. Automation and AI help to calculate exact costs. This makes the ordering process more efficient.

Plastic lenses are a good investment for the future. They impress with their quality and innovative solutions. Discover our products and find out more about their benefits for your projects.

FAQ

What are the advantages of plastic optical lenses?

Plastic lenses are lightweight and shatterproof. They are cost-efficient and have great optical properties. They also offer better UV protection and are versatile, especially in ophthalmic optics and medical technology.

What materials are used to manufacture plastic lenses?

We use modern materials such as polycarbonate and CR-39, which are durable and clear. They help us to create innovative solutions.

How does the ordering process for plastic lenses work?

The ordering process is simple. You can upload your 3D file on our website. Then we calculate the cost and you can track your order. It’s quick and easy.

What applications are there for plastic lenses?

Plastic lenses are used in many areas. These include spectacles, contact lenses, optical devices and cameras. They are versatile and ideal for medical technology, photography and more.

How do you care for plastic optical lenses properly?

Clean your lenses regularly with a microfiber cloth and special products. Store them in a dry, cool place. This will keep them in good condition for a long time.

What are the differences between plastic and glass lenses?

Plastic lenses are more flexible and robust than glass lenses. They are therefore more popular in many applications. Glass lenses are more scratch-resistant, but plastic lenses are lighter and shatterproof.

How do technological advances contribute to lens production?

Digitalization and AI are revolutionizing our production. They enable more precise production and reduce costs. This improves quality and shortens delivery times.

What are the trends in the plastics industry?

There is increasing demand for environmentally friendly materials and technological innovations. These developments offer new opportunities for companies in the sector.