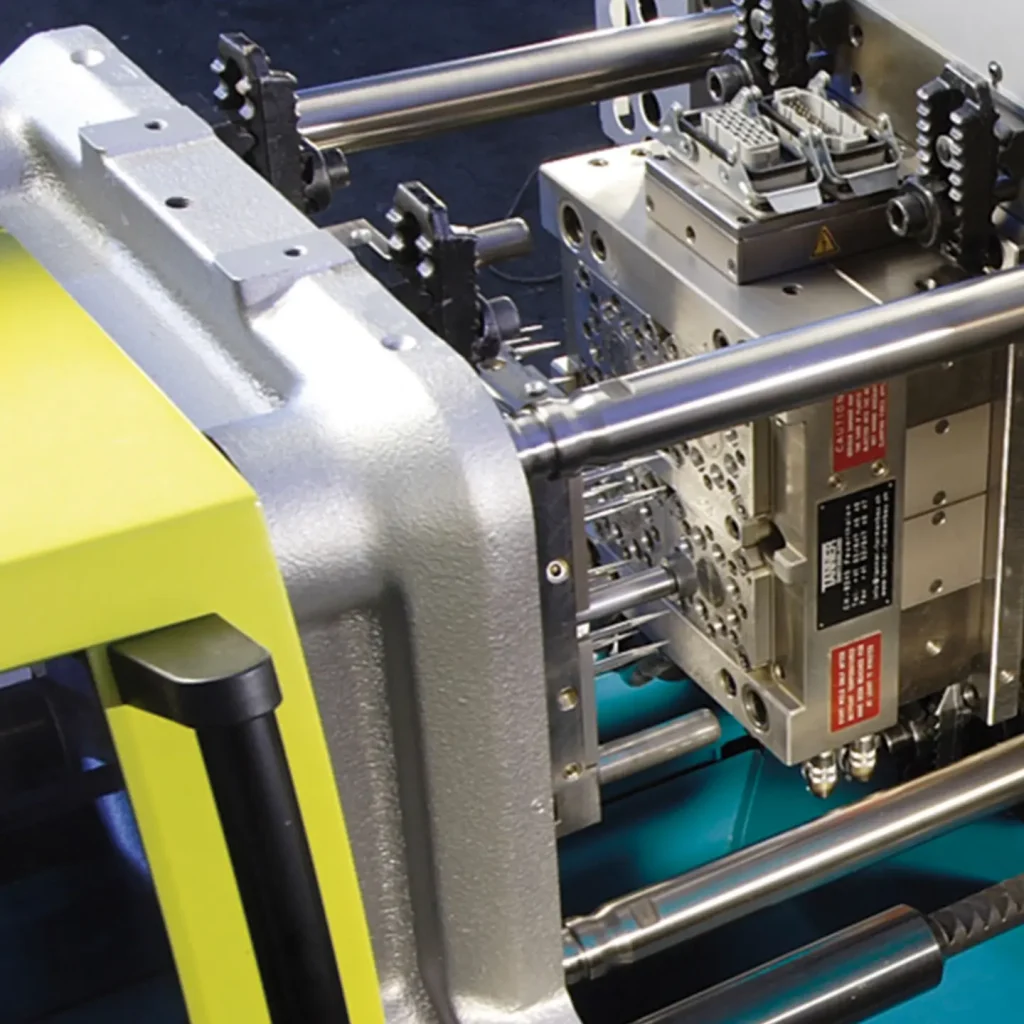

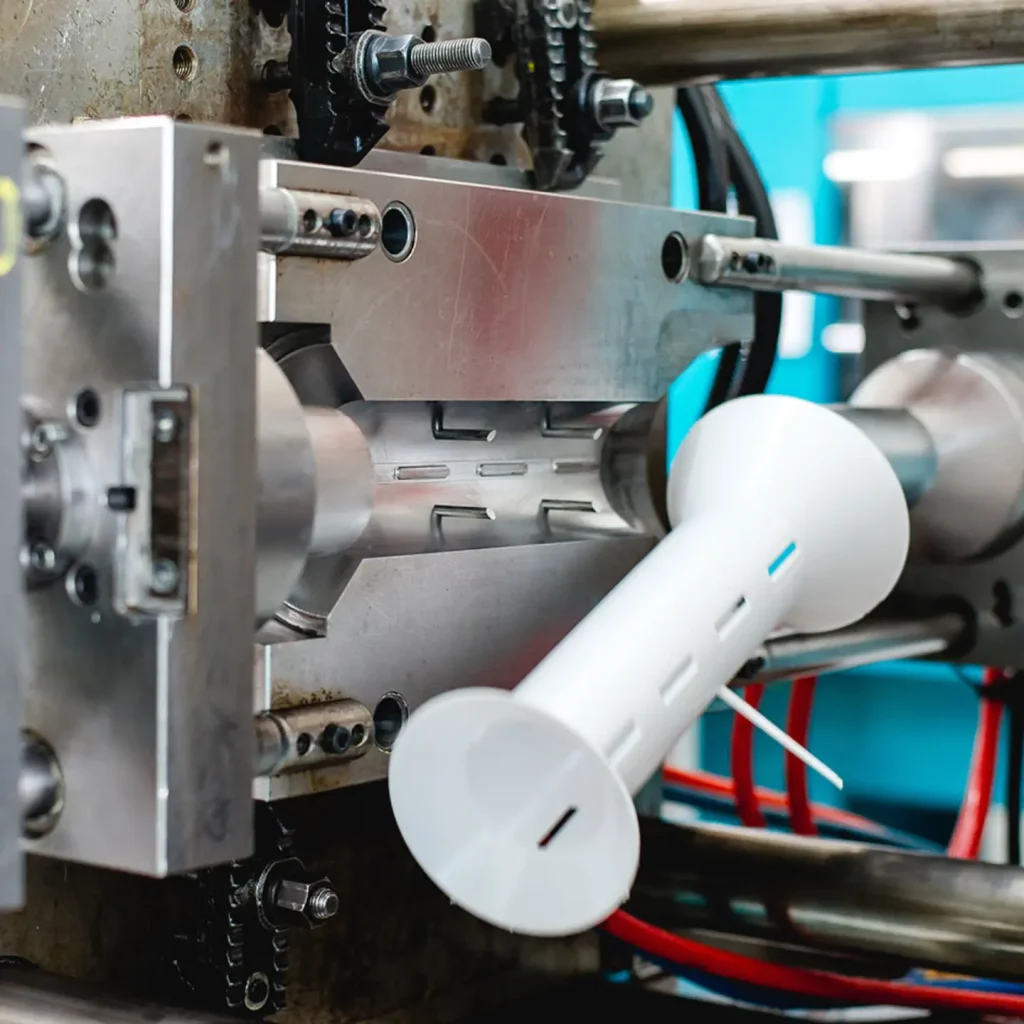

overmolding of inserts

- First technical injection-molded parts in just a few days

- Automated & certified

- offer in a few hours

- Technical injection-molded parts in just a few days

- Automated insertion

- offer in a few hours

Over 200+ companies

trust maxnext

Overmolding inserts to ensure dimensionally stable performance.

Technical components for electronics and electrical systems. Permanently connected for safe applications.

Fast, personal communication and best price directly in the first offer.

small and large series

Inserts directly from the overmolding directly from the manufacturer

Joining metal & conductor materials with plastic

Especially when different materials have to be combined, things can quickly become complex.

We at maxnext support you in choosing the perfect materials and automating these processes. From simple components to complex assemblies.

Let’s get it started!

“Our goal was to optimize the existing plastic housings of our access points. The result: We are now independent & the purchase has become more economical.”

Winfried Zangerle

CEO @ germanhotspot.de

“Quick implementation of our product design. We never thought it would make such an extreme difference to our sales. Thank you!”

André Becker

CEO @ expertenloft

1000+ successful projects per year!

- Simple and complex assemblies

- The partner for plastic molded metal parts

- offer in a few hours

-

multi-component injection molding

-

fiber-reinforced components

-

welding & finishing

-

assembly of components

2k and 3K injection molded parts

We manufacture composite plastic parts according to your requirements from a wide range of thermoplastics, such as ABS, PET, POM, PC, PA, PP, PS, PEEK and other engineering plastics. As one of the few plastic injection molding plants, we ourselves produce larger assemblies that are assembled from individual parts. More on the topic of multi-component production

Ideal for use with electricity.

Perfect insulating properties & fire protection thanks to fiber reinforcement. More about flame retardants in plastics.

welding plastic parts

We offer the optimal welding process for all common plastics with our plastic welders trained according to DVS 2281.

- hot gas welding,

- Heating element butt welding and

- ultrasonic welding

cover all possible requirements in our plastics sector. Unlike alternative methods such as riveting or screwing, welded joints ensure liquid- or gas-tight seams with a mostly smooth, flawless surface without notch effect. Depending on the process, this result can be refined to the maximum. Some joints of individual components require a particularly even distribution of stress, which leads to highly resilient results with the appropriate plastic welding method.

We can even manufacture larger assemblies without any problems.

assembly and device construction

In the field of equipment construction, we manufacture functional and mechanical assemblies. To do this, we complete the plastic items produced for you with additional components such as circuit boards, switches, motors and cables, the purchase of which and the planning of which we are happy to take over for you. Final inspections, functional tests and serial number management are of course documented in a traceable manner.

Special requests and individual designs are possible at any time!

certifications

… we have that too. In our factory near Augsburg, we overmold inserts according to DIN ISO without being certified. That saves money.

Our injection moulding plant near Nuremberg is certified to DIN ISO 9001 & 14001: ideal for anyone who values this.