Flipcap lids are becoming increasingly popular in the packaging industry. They enable high precision thanks to advanced injection molding processes. This technology meets the requirements of many industries.

Manufacturers and consumers benefit from these lids. They are efficient and sustainable. The lids are both functional and beautiful.

Key findings

- Flipcap lids are innovative and versatile packaging solutions.

- Modern injection molding enables precise and efficient production.

- Ideal for various industries, including food and cosmetics.

- Ensuring high quality standards through advanced processes.

- The demand for sustainable packaging solutions is constantly growing.

Introduction to flipcap lid technology

Flipcap technology is a great packaging innovation. It fulfills the wishes of modern consumers. Flipcap lids are hinged lids that are easy to use and seal well.

An important aspect of flipcap lids is the injection molding technique. This technique makes it possible to design and produce lids precisely. This means that the lids are not only useful, but also durable.

Flipcap lids are used in many areas. From food to the cosmetics industry. The versatility of flipcap technology is demonstrated in injection molding technology.

Advantages of flipcap lids in injection molding

Flipcap lids have many advantages that come from injection molding. They help companies to save money because they can produce many pieces cheaply. This makes the production process more efficient.

A big plus point is the high level of precision during production. This ensures lids that fit perfectly. This guarantees a good seal and a better user experience.

- Customizable designs offer versatility for different applications.

- High production speeds increase efficiency.

- Reduced material waste leads to cost savings.

Flipcap lids offer companies a reliable packaging solution. They are economical and practical.

Flipcap-Deckel im Spritzgussverfahren - Präzise Produktion

The production of flipcap lids requires a great deal of care and technical precision. We take a look at what influences the production of these innovative lids.

Technical precision in production

You need first-class knowledge to make them. Every detail is important to get everything just right. We control the quality during the injection molding process.

This enables us to achieve the necessary technical precision. We pay particular attention to shape and attention to detail. This ensures that the flipcap lids remain functional for a long time.

Material selection for durable solutions

The choice of material is crucial for durability. We use high-quality plastics such as PET and PP. These are durable and withstand chemicals well.

The right choice of material ensures that the flipcap lids remain robust. This means they last longer in use.

Areas of application for flipcap lids

Flipcap lids are used in many areas. They are not only practical, but also attractive. This is particularly important in the food and cosmetics world. We look at how these lids meet specific needs in packaging solutions.

Food packaging

When it comes to food packaging, hygiene and user-friendliness count. Flipcap lids are easy to use and protect the contents. They meet the high standards of the food industry.

Cosmetics industry

In the cosmetics industry, flipcap lids improve presentation and functionality. They offer elegant packaging that looks good and is practical. This is how they meet the needs of consumers.

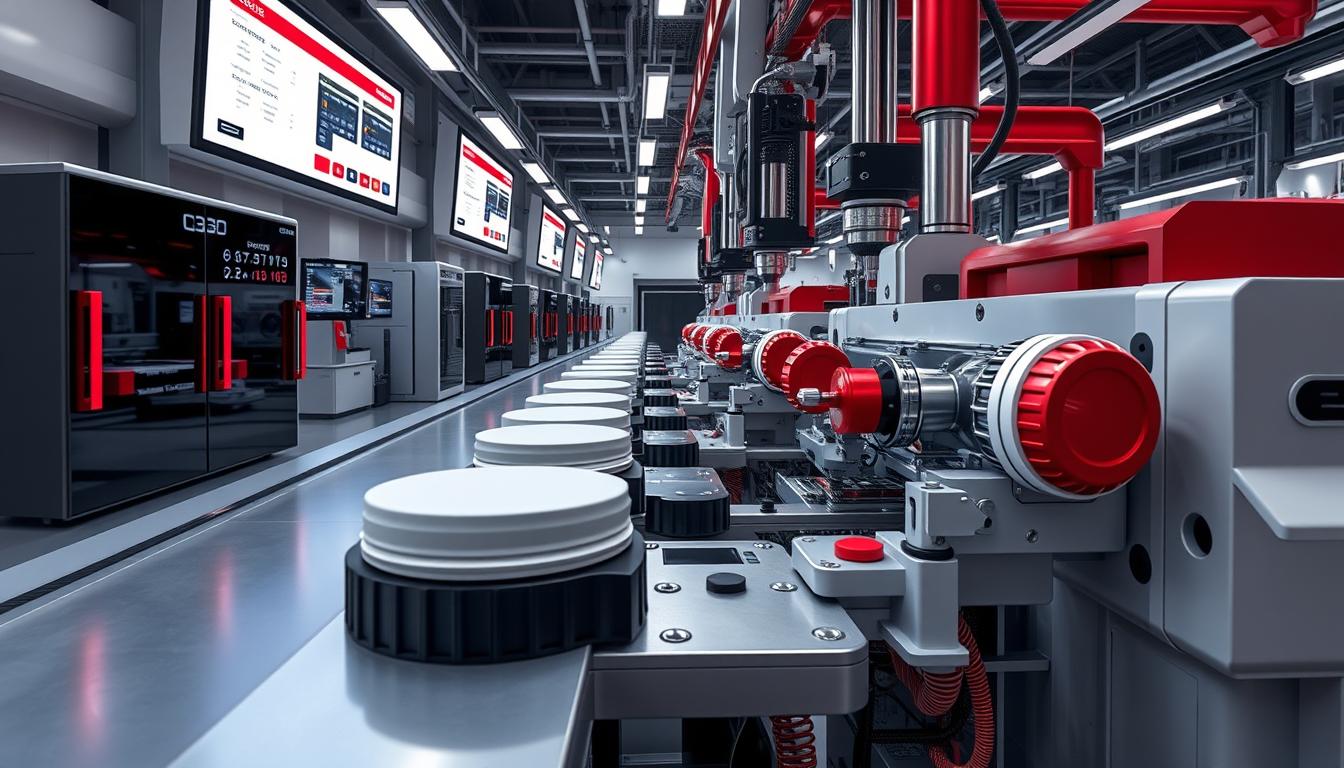

The injection molding process explained

The injection molding process is an important part of production technology. It enables the precise production of flipcap lids. First, plastic granulate is heated in a machine until it melts.

The temperature and pressure are precisely controlled. This is how the right consistency is achieved.

After melting, the material is injected into a mold. This mold has the shape of the lid. This enables detailed designs.

One major advantage of injection molding is its efficiency. The production lines work continuously. They produce many flipcap lids in a short time.

The quality of the lids depends on precise control. Incorrect temperatures or too little pressure can cause faults.

The choice of material is also important. Bio-based materials such as Terralene® are often used. They are environmentally friendly and have the necessary properties for a long shelf life. You can find more information under Flipcap lids made of bioplastics.

Quality control for flipcap lids

This section is about quality control. We carry out various test procedures. These ensure that the flipcap lids not only look good, but also work well. Certifications are also important because they give customers confidence in our products.

Test procedure to ensure functionality

We test the flipcap lids thoroughly. In doing so, we check:

- Material for durability and resistance

- Functions at different temperatures

- Tightness and stability

Every test procedure helps us to fulfill our customers’ wishes. This is how we ensure that the products work well.

Importance of certifications

Importance of certifications Certifications are very important to us. They show that our flipcap lids are of high quality and safe. They give our customers confidence and help us to grow internationally.

- Trust from our customers

- Market access in regulated industries

- Compliance with international standards

We achieve the highest standards in our industry through specific certifications.

Market development and trends

The packaging industry is undergoing exciting changes, especially for flipcap lids. Companies need to find creative solutions that are environmentally friendly. The trend is towards biodegradable and recyclable materials.

Consumers show in their purchasing decisions that they value sustainability. This shows how important sustainability has become in the packaging industry.

An important point in market development is the adaptability of the products. Flipcap lids are not only useful, but also fit well into sustainable concepts. They help to increase the pressure to innovate in the industry and meet ecological requirements.

The demand for flexible packaging is growing. Products such as jacket packaging and simple designs are making flipcap lids more popular. They show how technical solutions can follow the trends in the packaging industry.

For more information on innovative packaging production, visit extrusion solutions.

Future outlook for flipcap lids in injection molding

The future of flipcap lids in injection molding looks promising. New technologies play a major role in this. AI and automation could make production more efficient and precise.

Technological advances and changes in supply chains are influencing development. Individual customer requirements also play a role. Our company is adapting to these changes.

- Increasing demand for custom flipcap lids

- Optimization of production costs through automated processes

- Integration of sustainable materials in the manufacturing process

We provide insights into the production of flipcap lids. In our article on small series and 3D printing, we show developments in the production process.

| Factor | Effect |

|---|---|

| Technological | progressIncreased precision and efficiency |

| Customer-specific adaptations | Strengthening the market position |

| Sustainable choice of | materialsImproved environmental footprint |

The future of flipcap lids in injection molding promises exciting developments. We are constantly preparing for this evolution.

Conclusion

Flipcap lids in injection molding are a great solution for production. They offer precision and efficiency. They set new standards in the packaging industry.

The advantages of injection molding are clear. They improve added value in many areas. This shows how important flipcap lids are.

Flipcap lids are versatile and customizable. They suit many markets. In a world that values innovation and sustainability, they are very important.

Companies that invest in flipcap lids are well prepared. They are ready for the future.

We invite you to work with us. So we can benefit from the advantages of injection molding. Let’s build a successful partnership based on the latest trends!

FAQ

What are flipcap lids and what are they used for?

Flipcap lids are a modern way of closing things. They are particularly popular in the packaging industry. They are easy to use and work very well.

How does the injection molding process for flipcap lids work?

In the injection molding process, plastic granulate is heated and shaped. The temperature and pressure must be precisely controlled. This is how high-quality flipcap lids are produced.

What materials are used to make flipcap lids?

We use PET and PP because they are durable and robust. These plastics ensure that the lids last a long time.

What advantages do Flipcap lids offer compared to other packaging solutions?

They are inexpensive to produce in large quantities. They fit perfectly and are customizable. This makes them very useful.

How is the quality of the flipcap lids ensured?

We carry out many tests to check the quality. Aesthetics and functionality are checked. Certifications show that our products are safe and of high quality.

In which sectors are flipcap lids used?

They are very popular in food packaging and in the cosmetics industry. They offer hygienic and elegant solutions.

What trends can currently be observed in the market for flipcap lids?

Sustainability and environmental awareness are current trends. Companies are looking for environmentally friendly solutions. Flipcap lids can help here.

What are the future developments in the production of flipcap lids?

New technologies such as AI and automation are being used. These innovations improve the production process and fulfill individual customer wishes.